What is a Halcon Calibration Target?

Halcon calibration targets are precisely manufactured physical objects with known geometric properties that serve as reference patterns for camera and machine vision system calibration. These specialized targets enable Halcon software to determine critical camera parameters including focal length, lens distortion, and spatial positioning, transforming standard cameras into accurate measurement instruments.

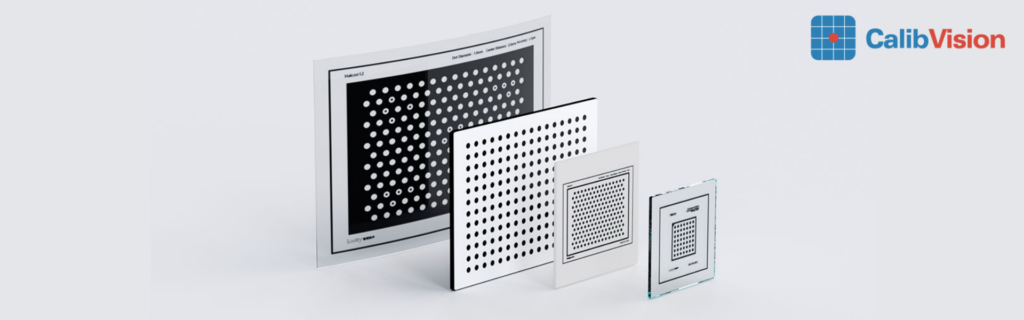

The calibration process involves capturing multiple images of the target from various angles and positions, allowing Halcon’s algorithms to analyze the known patterns and calculate precise camera parameters. Common target types include circular dot arrays, checkerboard patterns, and hexagonal arrangements, with customization options available through Halcon’s create_caltab operator.

These targets are essential for applications requiring high-precision measurements, including quality control inspection, robot guidance, 3D scanning, and dimensional analysis. By providing sub-pixel accuracy and correcting lens distortion effects, Halcon calibration targets enable reliable and consistent results across different operational conditions.

The proper selection and implementation of calibration targets significantly impact system performance, with factors such as working distance, accuracy requirements, environmental conditions, and target material playing crucial roles in achieving optimal calibration results. Professional implementation typically involves capturing 10-20 calibration images with the target filling approximately one-third to two-thirds of the camera’s field of view for maximum effectiveness.