Description

Intelligent Measurement Assistant System

The SVI4K-0745 simplifies precise measurements with its smart visual inspection capabilities. Unlike conventional systems, it requires no manual calibration before use – just power on, select a tool, and define your measurement area. The system handles the rest automatically, finding features and calculating measurements with exceptional accuracy.

| Model NO. | Camera Info | Lens Info | Adjustment Mode | Image | Field of View |

| SVI4K-0745B | 4K, Sony sensor, 1/2″ | 0.7-4.5x zoom lens | Linear adjustment | 4K color | 50mm |

| SVI4K-0745G | 4K, Sony sensor, 1/2″ | 0.7-4.5x zoom lens | Fixed magnification adjustment | 4K color | 100mm |

| SVI4K-0745D | 4K, Sony sensor, 1/2″ | 0.7-4.5x zoom lens with large depth of field | Linear adjustment | 4K color | 100mm |

3 Simple Steps to Precise Measurement

-

Power On – System initializes with automatic calibration

-

Select Function – Choose from 18 built-in measurement tools

-

Define Range – Select the area to measure

The system automatically recognizes features within your defined area and performs accurate measurements at high speed.

Key Features

-

Auto-Calibration Technology: Measure directly without tedious calibration procedures

-

Automatic Feature Recognition: System identifies measurement points after you select the tool

-

One-Click Image Export: Capture and save high-resolution images with measurements

-

One-Click Data Export: Generate measurement data tables instantly

-

Smooth 4K Imaging: 60 FPS video feed provides clear, blur-free viewing

-

Versatile Magnification: Continuous 0.7X-4.5X zoom range (model dependent)

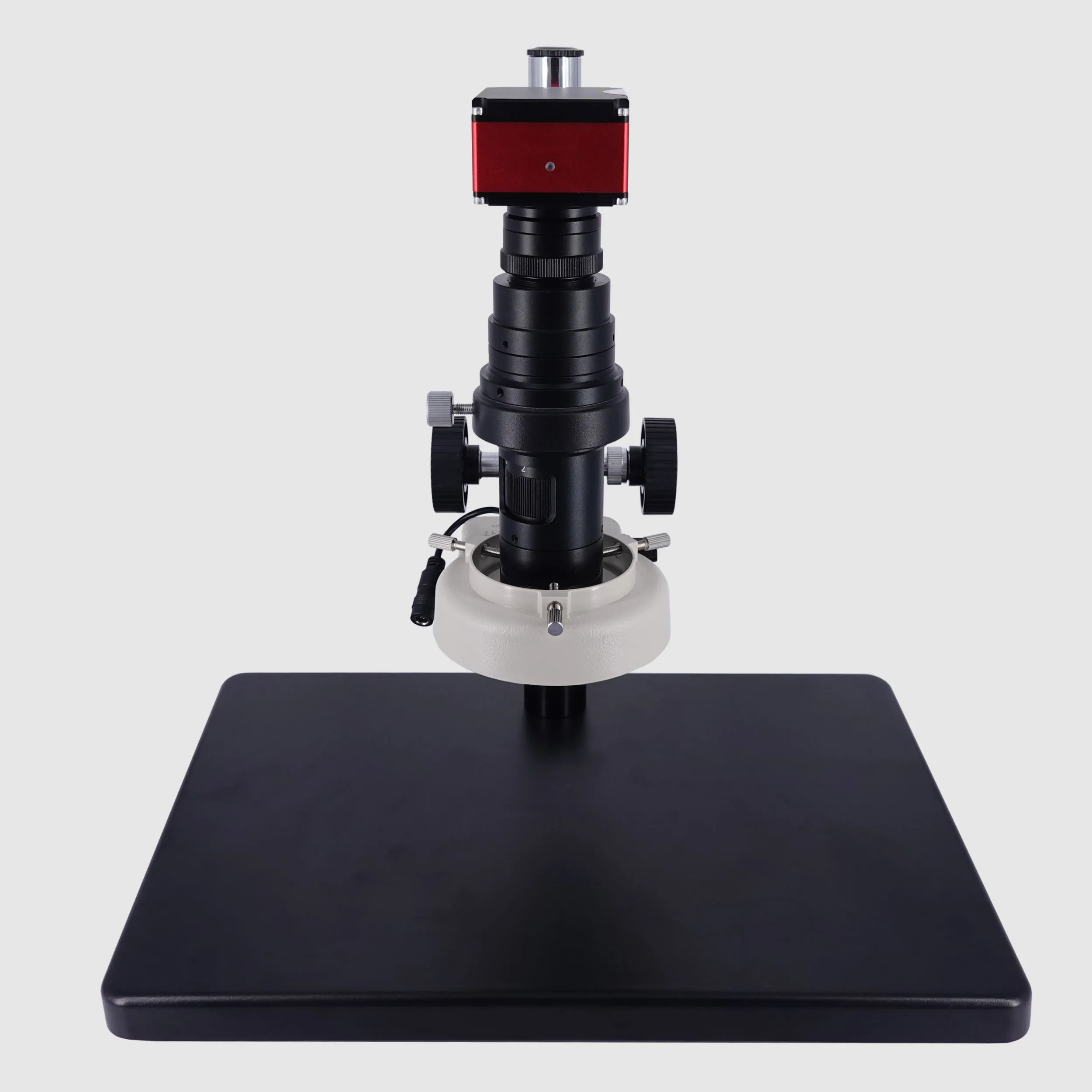

What are included in this Vision System?

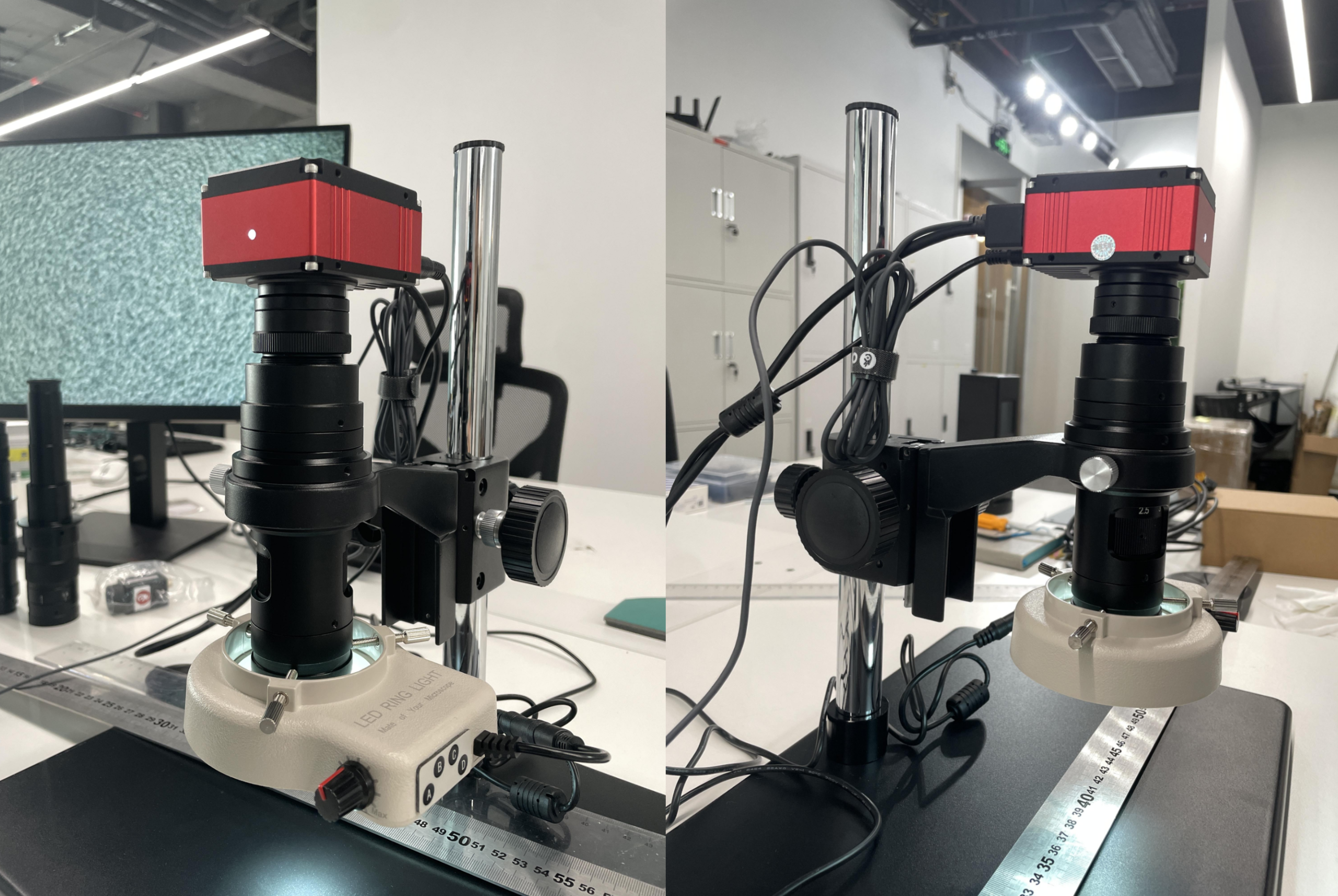

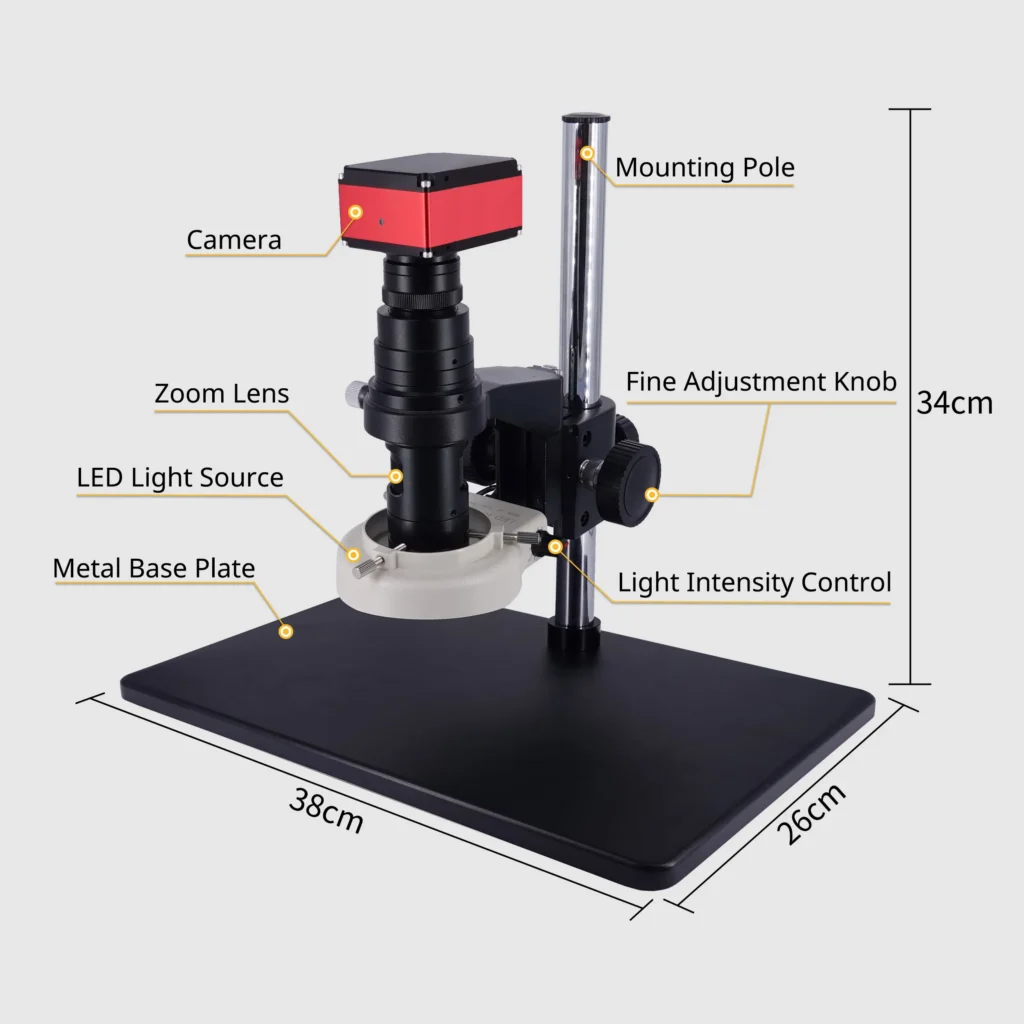

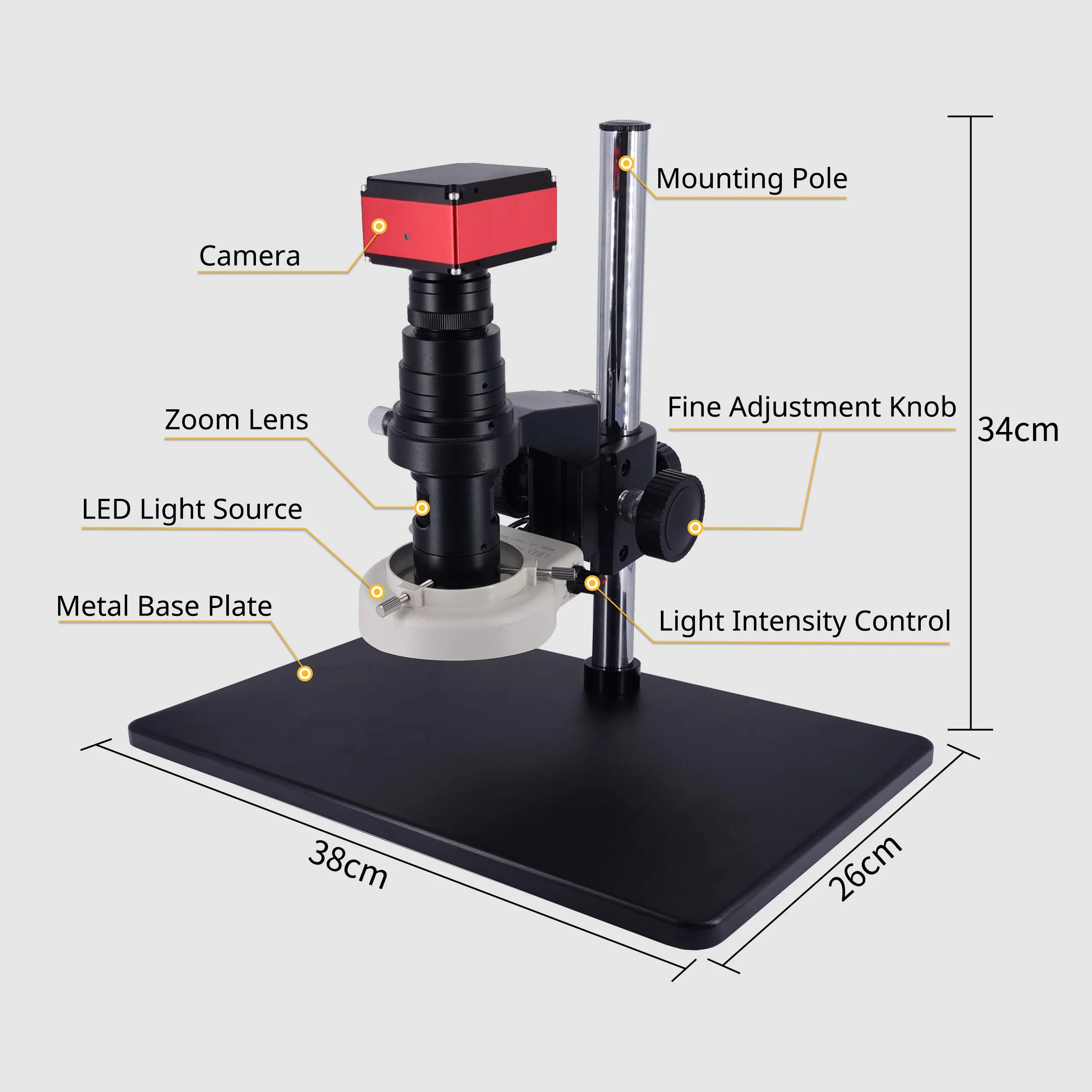

Main Camera Stand

-

Camera: Industrial camera with high-resolution sensor

-

Mounting Pole: 34cm height support column

-

Zoom Lens: Variable magnification optics

-

LED Light Source: Built-in illumination

-

Fine Adjustment Knob: Precision focus control

-

Light Intensity Control: Brightness adjustment

-

Metal Base Plate: Stable platform (38cm × 26cm)

LED Ring Light

-

Mounting Brackets: Secure attachment system

-

Light Intensity Control: Brightness adjustment dial

-

Segment Control Switches: A/B/C/D quadrant lighting selectors

Optical Components

-

C-Mount Interface: Standard lens connection

-

Magnification Scale: Zoom level indicator

-

Magnification Adjustment Ring: Focus control

Camera Interface

-

Power Input: Main connection port

-

USB 2.0 Port: Data transfer connection

-

USB 3.0 Port: High-speed data transfer

-

GigE Connection: Network interface

-

HDMI Output: Direct display connection

This complete system provides precision imaging capabilities for industrial inspection, measurement, and quality control applications.

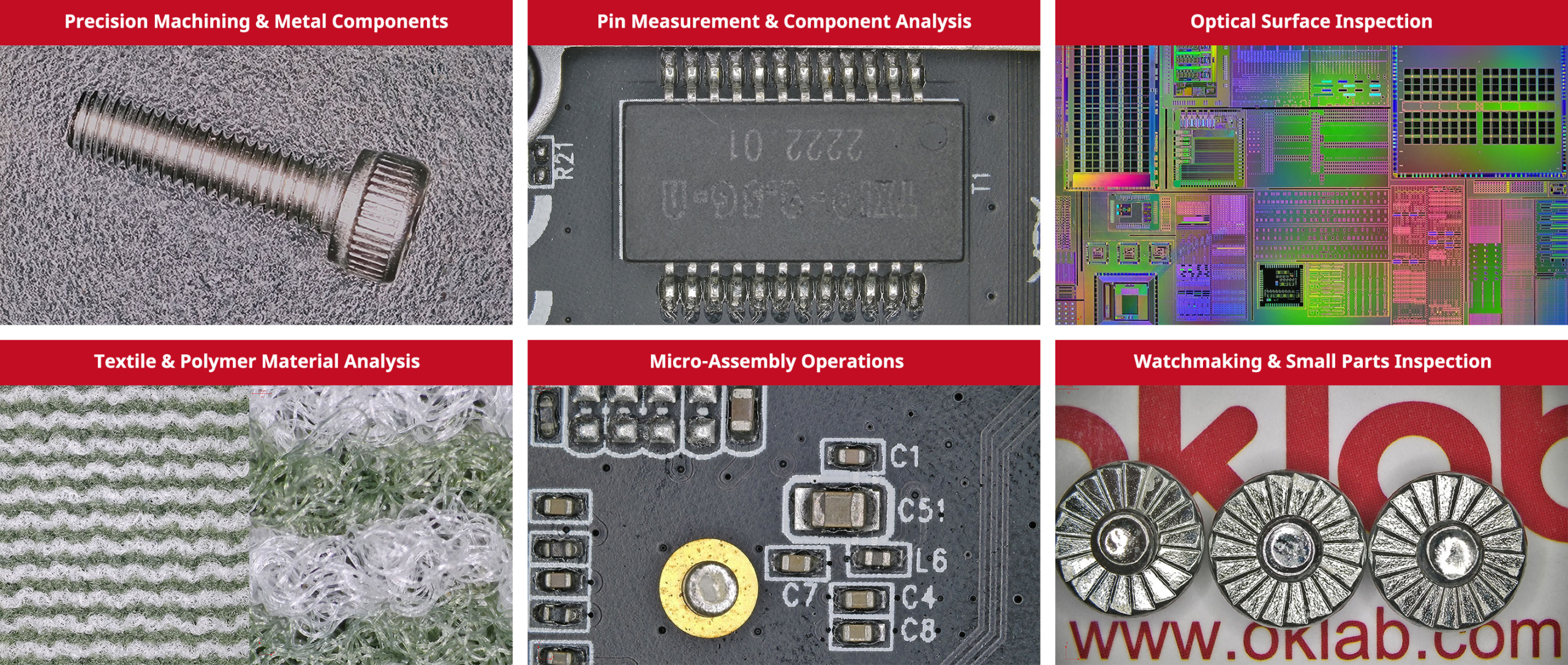

All-in-One Smart Inspection Solutions for Every Industry

Our vision systems deliver precision measurement and quality control across diverse applications, streamlining your workflow with intuitive technology that adapts to your specific needs.

- Electronic Components

-

Pin measurements on microchips

-

Solder ball inspection

-

Gold wire measurements

-

PCB inspection

-

Manufacturing Quality Control

-

Small metal part measurements

-

Watch component inspection

-

Fine defect detection

-

Materials Analysis

-

Lens and wafer scratch/contamination detection

-

Polymer material analysis

-

Fabric and textile inspection

-

Precision Operations

-

Micro-assembly assistance

-

Small component soldering

-

Detailed visual inspection

Industries Served

-

Semiconductor

-

SMT/Electronics Manufacturing

-

Textile

-

Electronic Components

-

Materials Testing

-

Precision Manufacturing

-

Quality Assurance/Quality Control

-

PCB Manufacturing

Why Choose the SVI4K-0745?

The SVI4K-0745 stands out for its combination of high-resolution imaging, intelligent software, and user-friendly operation. It eliminates the complexity typically associated with precision measurement systems, allowing even novice users to obtain accurate results quickly.

Unlike traditional systems that require extensive setup and calibration, the SVI4K series works right out of the box, saving valuable time and reducing the potential for human error. The automated feature recognition significantly speeds up repetitive measurement tasks while maintaining exceptional accuracy.

Choose from three models to match your specific needs – continuous zoom adjustment (B model), fixed-step zoom (G model), or specialized deep field lens (D model) for specialized applications.

Reviews

There are no reviews yet.