Custom Calibration Target Selection

Guide Overview

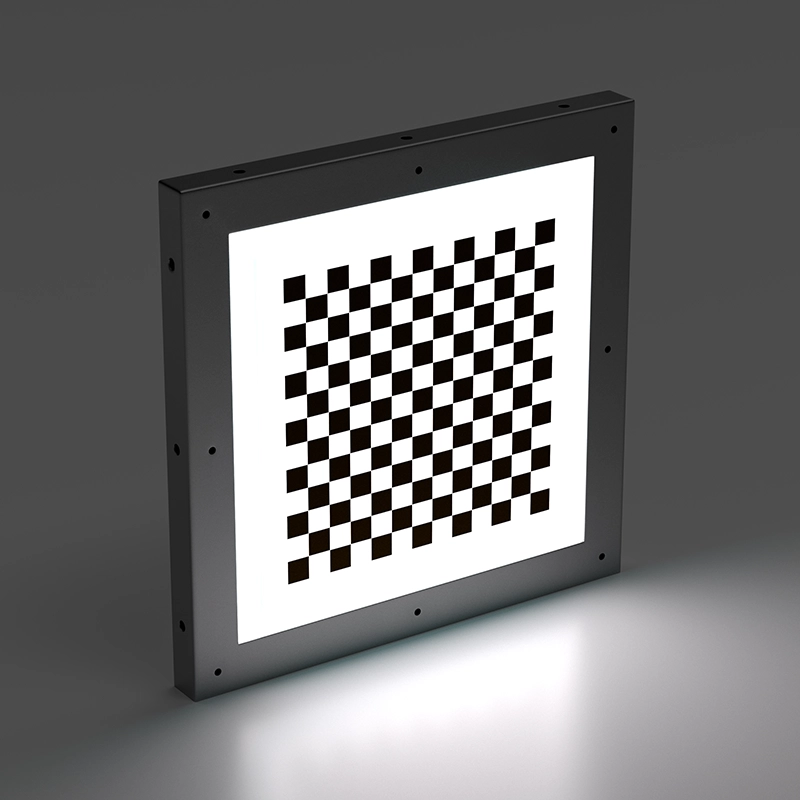

Backlight & Transmission Illumination Solutions

|

|

|

|

|

|---|---|---|---|---|

|

Chrome on soda lime glass (float glass) |

Chrome on quartz glass (fused silica) |

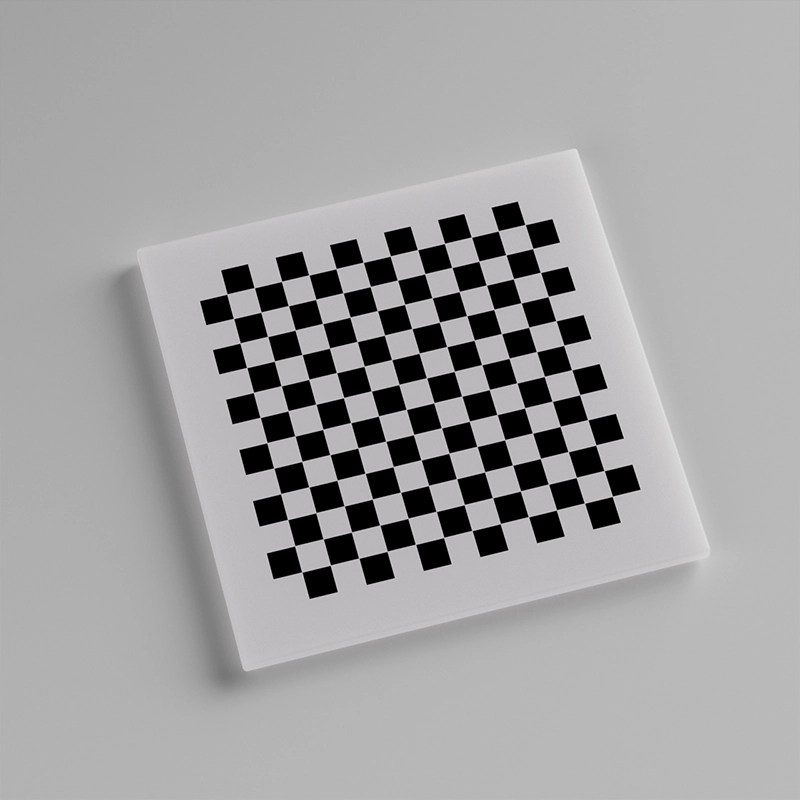

Photosensitive Ink on Float Glass |

Chrome on glass target with backlight |

|

|

Ultimate Solution |

||||

|

Min. Feature Size |

2µm | 0.5µm | 80µm | 0.5µm |

|

Feature size Accuracy |

±1µm | ±1µm, ±0.1µm, ±0.05µm | ±10µm | ±1µm, ±0.1µm, ±0.05µm |

|

Feature Spacing Accuracy |

±1µm | ±1µm, ±0.1µm, ±0.05µm | ±10µm | ±1µm, ±0.1µm, ±0.05µm |

|

Feature Position Accuracy |

Dimension ≤ 300mm: ±0.001mm | Dimension ≤ 300mm: ±0.001mm |

Pattern Area 0~200mm: within 30µm |

Dimension ≤ 300mm: ±0.001mm |

| Dimension > 300mm: ±0.002~0.005mm | Dimension > 300mm: ±0.002~0.005mm | Pattern Area 200~300mm: within 40µm | Dimension > 300mm: ±0.003~0.005mm | |

| Pattern Area 300~400mm: within 50µm | Pattern Area 300~400mm: within 50µm | Pattern Area 300~400mm: within 50µm | Pattern Area 300~400mm: within 50µm | |

| Pattern Area 400~500mm: within 60µm | Pattern Area 400~500mm: within 60µm | Pattern Area 400~500mm: within 60µm | Pattern Area 400~500mm: within 60µm | |

| Pattern Area 500~600mm: within 70µm | Pattern Area 500~600mm: within 70µm | Pattern Area 500~600mm: within 70µm | Pattern Area 500~600mm: within 70µm | |

|

Max. Overall Dimension |

1092 x 813mm | 1200 x 850mm | 2500 x 1580mm | 1200 x 850mm |

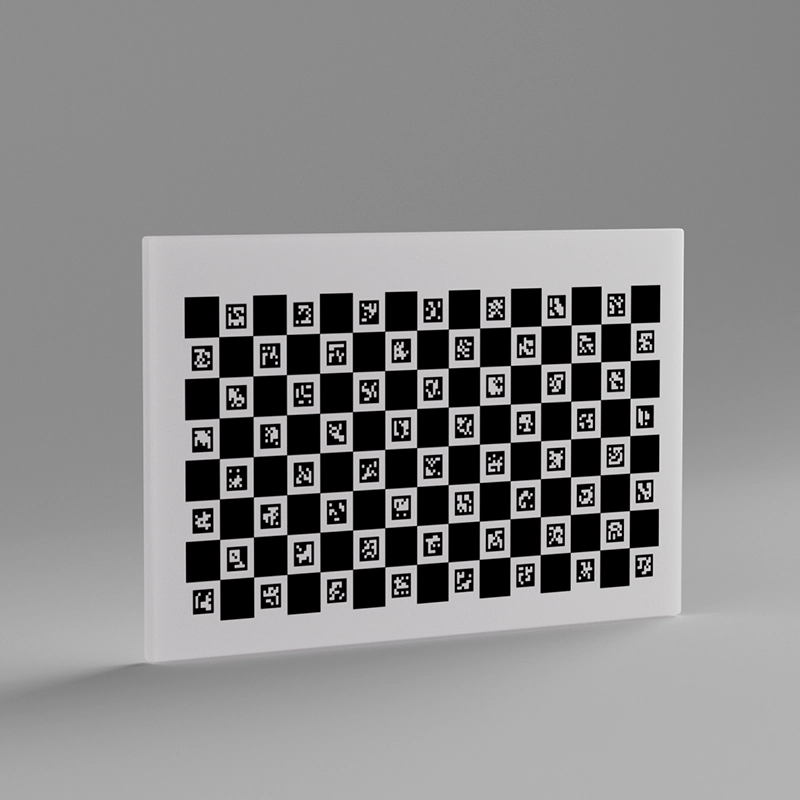

Front & Reflective Illumination Solutions

|

|

|

|

|

|---|---|---|---|---|

| Chome on Ceramic Sunbstrate |

Photosensitive Ink on Carbon Fiber |

High resolution printing on aluminum |

Photosensitive ink on aluminum |

|

|

Ultimate Solution |

||||

|

Min. Feature Size |

10µm | 80µm | 80µm | 80µm |

|

Feature size Accuracy |

±3µm | ±10µm | ±10µm | ±10µm |

|

Feature Spacing Accuracy |

±3µm | ±10µm | ±10µm | ±10µm |

|

Feature Position Accuracy |

±0.002mm | Pattern Area 0~200mm: within 30µm | Pattern Area 0~200mm: within 30µm | Pattern Area 0~200mm: within 30µm |

| ±0.002mm | Pattern Area 200~300mm: within 40µm | Pattern Area 200~300mm: within 40µm | Pattern Area 200~400mm: within 40µm | |

| ±0.002mm | Pattern Area 300~400mm: within 50µm | Pattern Area 300~400mm: within 50µm | Pattern Area 300~400mm: within 50µm | |

| ±0.002mm | Pattern Area 400~500mm: within 60µm | Pattern Area 400~500mm: within 60µm | Pattern Area 400~500mm: within 60µm | |

| ±0.002mm | Pattern Area 500~600mm: within 70µm | Pattern Area 500~600mm: within 70µm | Pattern Area 500~600mm: within 70µm | |

|

Max. Overall Dimension |

228 x 228mm | 2500 x 1580mm | 2500 x 1580mm | 2500 x 1580mm |

How to select the right substrate material and proper manufactruing process for your custom test targets?

STEP 01: To Select Right Substrate Material

The operating environment (transmission, reflective or natural illumination) is essential to select either transparent or opaque material. Transparent material is for example soda lime glass, quartz glass, acryl or film. For reflective illumination/ natural illumination applications opaque material such as matte ceramic, aluminum and carbon fiber boards are your options.

STEP 02: Confirm Proper manufactruing process

The required accuracy is the important parameter when selecting the manufacturing process. The feature size accuracy of Photosensitive ink pattern as an example is +/-10um while the accuracy of Chrome pattern from Direct Laser Writing lithography process is +/-1um, +/-0.1um; Besides accuracy, the smallest line width or minimum feature size is also a critical parameter. The limitation of Chrome pattern from Direct Laser Writing lithography process is 0.5um while Photosensitive ink exposuring process allows feature sizes down to 0.08mm.