Why Calibration Targets Are Needed?

To achieve high-precision measurement results, calibration is an essential step. Just like a new car needs fine-tuning before hitting the road, optical measurement equipment requires precise calibration to deliver peak performance.

Lens Distortion is a Universal Reality

The truth is, there’s no such thing as a perfect lens. Whether it’s a telecentric lens or a standard lens, all optical systems have some degree of distortion. Think of it like wearing glasses – there’s always some tiny warping when you look through them.

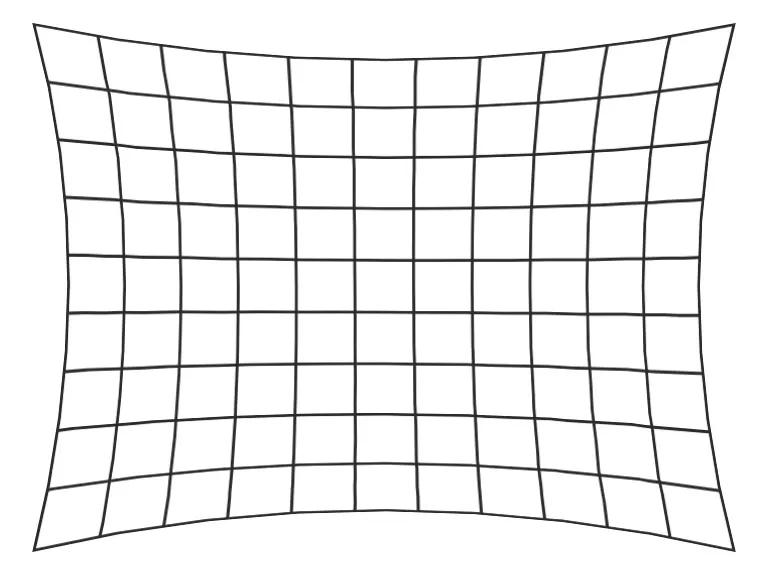

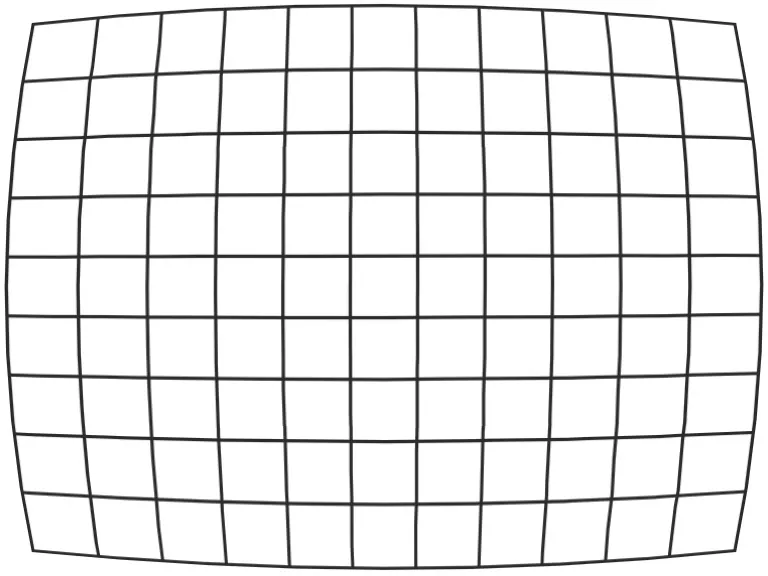

Common distortion types include barrel distortion (where images bulge outward, see figure 1 below) and pincushion distortion (where images curve inward, see figure 2 below). Beyond these, if your camera isn’t installed perfectly parallel to the subject, or if there’s slight misalignment between the camera and lens, you’ll get what’s called “keystone distortion.”

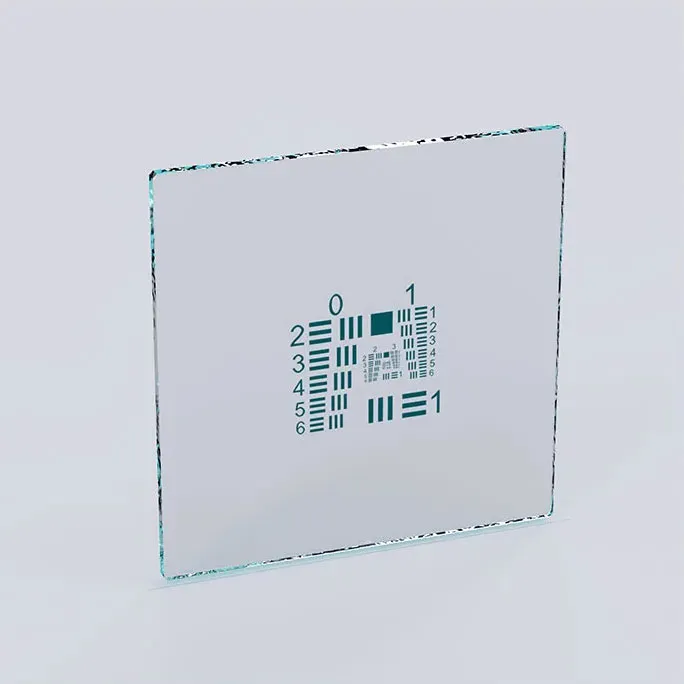

Calibration Targets Solve the Problem

A Real-World Example Makes It Clear

For many applications, 0.1mm error might be perfectly acceptable. But if your application demands higher precision, we can use a calibration target to correct and completely eliminate this error.

Calibration Target is the Secret Behind High-Precision Systems

Calibration technology is the key difference between ordinary measurement systems and high-precision systems. Through proper calibration, we can upgrade measurement accuracy from millimeter-level to micrometer-level or even higher. It’s like upgrading from a basic ruler to a precision measuring instrument.

Systems without calibration can only provide basic accuracy, while professionally calibrated systems achieve true high-precision measurement. This difference often determines product quality levels and production efficiency outcomes.