Introduction

In the world of precision optical measurement, the calibration target is the foundation upon which all accuracy depends. Whether you’re calibrating cameras for autonomous vehicles, setting up stereo vision systems for robotics, or conducting research in machine vision, the quality of your calibration target directly determines the reliability of your results.

Yet not all calibration targets are created equal. The difference between a professionally manufactured target and a consumer-grade alternative can mean the difference between sub-pixel accuracy and measurement errors that propagate through your entire system. While a printed checkerboard pattern might look visually similar to a photolithography-manufactured chrome-on-glass target, the performance gap is dramatic—often 10 to 50 times in terms of edge sharpness and dimensional precision.

This article explores the manufacturing standards, processes, and quality control measures that separate professional-grade calibration targets from alternatives. We’ll take you inside CalibVision‘s cleanroom manufacturing facility to show exactly how precision calibration targets are made, and why these standards matter for your application.

What you’ll learn:

- How calibration target quality directly impacts measurement accuracy

- The critical quality parameters that define professional-grade targets

- Inside cleanroom manufacturing: photolithography and precision processes

- Six-stage quality control that ensures zero-defect delivery

- Application-specific requirements across industries

- How to evaluate supplier quality and avoid common pitfalls

The Foundation of Accurate Camera Calibration

How Calibration Targets Work

Camera calibration is fundamentally a measurement problem. To determine intrinsic parameters (focal length, principal point, distortion coefficients) and extrinsic parameters (rotation and translation in 3D space), computer vision algorithms need to identify precise reference points in the image.

Calibration targets provide these reference points through high-contrast patterns—typically checkerboards, dot grids, or ChArUco boards. The algorithm detects corners or feature centers in the captured image, then compares their pixel locations to the known physical dimensions of the pattern.

The calibration workflow:

- Feature Detection: Algorithm identifies corners/dots in the image

- Sub-Pixel Refinement: Corner locations refined to sub-pixel precision (typically 0.01 to 0.1 pixels)

- Correspondence: Image features matched to physical target coordinates

- Parameter Optimization: Camera parameters calculated via non-linear optimization

- Validation: Reprojection error measured (target: <0.1 pixel RMS)

This process requires the target’s physical dimensions to be extremely accurate. If the printed checkerboard square is supposed to be 30.00mm but is actually 30.15mm (±0.5% error), that dimensional error propagates directly into the calculated camera parameters.

The Measurement Chain: Target → Camera → Algorithm

Calibration accuracy depends on three factors:

- Target Quality: Dimensional accuracy, edge sharpness, contrast

- Camera Quality: Sensor noise, lens aberrations, resolution

- Algorithm Quality: Corner detection robustness, optimization convergence

Most users assume their camera and software are the limiting factors. In reality, target quality is often the weakest link. A camera with 2.4μm pixels can theoretically achieve 0.01 pixel (24nm) positioning accuracy—but only if the target’s feature edges are sharp enough to enable sub-pixel corner localization.

Where Quality Compromises Impact Results

Edge Sharpness Affects Corner Localization

When a corner detection algorithm analyzes a checkerboard intersection, it looks for the point where four regions of different intensity meet. If the edge transition is sharp (abrupt change from black to white within 1-5μm), the algorithm can pinpoint the corner location to within 0.01 pixels.

But if the edge is fuzzy—typical of printed targets where ink bleeds into the paper fibers over 50-100μm—the algorithm sees a gradual transition. This ambiguity translates into positioning uncertainty of 0.5 to 2 pixels, degrading calibration accuracy by 50-200×.

Dimensional Errors Propagate Through Calibration

If your calibration target specifies 10mm square spacing but actually measures 10.05mm (±0.5% error), every camera parameter calculated using that target will inherit that error. For a typical calibration at 1-meter working distance:

- Focal length error: ±0.5% (e.g., 3000 pixels becomes 3015 pixels)

- Distortion coefficient error: Proportional to pattern size inaccuracy

- 3D reconstruction error: ±0.5% at all measured distances

In stereo vision systems, a 0.5% error in camera baseline measurement translates directly to 0.5% error in depth estimation—potentially catastrophic for applications like autonomous navigation or robotic manipulation.

Contrast Ratio Influences Detection Reliability

Corner detection algorithms rely on high contrast between pattern features and background. Professional photolithography targets achieve contrast ratios exceeding 1000:1 (chrome on glass), while printed targets typically deliver 5:1 to 20:1.

Low contrast leads to:

- Missed detections: Algorithm fails to find corners in poor lighting

- False positives: Noise or artifacts misidentified as features

- Reduced repeatability: Detection results vary between captures

- Limited working distance: Target only usable at close range with bright illumination

What Defines High-Quality Calibration Targets?

Critical Quality Parameters

Professional-grade calibration targets are characterized by five measurable quality parameters:

1. Feature Edge Sharpness

The transition zone between black and white features, measured as the distance over which intensity changes from 10% to 90% of maximum contrast.

- Photolithography (chrome on glass): <1μm edge transition

- Laser etching/ablation: 10-30μm edge transition

- Screen printing: 50-100μm edge transition

- Inkjet printing: 100-300μm edge transition

Why it matters: Edge sharpness directly determines sub-pixel corner localization accuracy. Sharper edges enable 0.01-pixel precision; fuzzy edges limit accuracy to 0.5-2 pixels.

2. Dimensional Accuracy

The deviation between specified and actual feature positions/sizes, measured via coordinate measuring machine (CMM) or optical metrology.

- Metrology-grade: ±0.5μm to ±1μm (for research, standards labs)

- Professional-grade: ±2μm to ±5μm (for industrial QC, automotive)

- Standard-grade: ±5μm to ±15μm (for general machine vision)

- Consumer-grade: ±50μm to ±300μm (printed patterns)

Why it matters: Dimensional errors propagate directly into calibrated camera parameters. For sub-pixel calibration accuracy, target dimensional tolerance should be <1/10 of pixel size.

3. Contrast Ratio

The ratio of maximum to minimum intensity (bright areas / dark areas), measured via spectrophotometer or camera.

- Chrome on glass (photolithography): >1000:1 contrast

- Laser-etched metal: 100:1 to 500:1 contrast

- Screen-printed paper: 5:1 to 20:1 contrast

- Inkjet-printed film: 10:1 to 50:1 contrast

Why it matters: High contrast ensures reliable feature detection across varying illumination conditions and camera exposures. Low contrast limits working distance and requires controlled lighting.

4. Spatial Uniformity

The consistency of pattern features across the entire target surface, measured as standard deviation of feature dimensions.

- Excellent uniformity: <±1% variation across entire pattern

- Good uniformity: ±1% to ±2% variation

- Acceptable uniformity: ±2% to ±5% variation

- Poor uniformity: >±5% variation (common in printed targets due to ink density variations)

Why it matters: Non-uniform patterns cause spatially varying calibration errors, particularly problematic for wide-angle lenses or large-format targets.

5. Long-Term Dimensional Stability

The target’s ability to maintain dimensional accuracy over time under environmental stress (temperature, humidity, UV exposure).

- Glass substrates: <0.1% dimensional change over 10+ years

- Ceramic substrates: <0.2% change over 10+ years

- Metal substrates: 0.2-0.5% change over 5-10 years (depends on thermal expansion)

- Paper/plastic substrates: 1-5% change over 1-3 years (warping, expansion/contraction)

Why it matters: Calibration parameters derived from an unstable target become invalid as the target’s dimensions change. Frequent re-calibration required for low-stability targets.

Manufacturing Method Comparison

| Manufacturing Method | Edge Sharpness | Dimensional Accuracy | Contrast Ratio | Typical Lifespan | Best Applications |

|---|---|---|---|---|---|

| Photolithography (Chrome on Glass) | <1μm | ±0.5μm to ±2μm | >1000:1 | 10-15 years | Metrology labs, automotive ADAS, semiconductor inspection, research |

| Laser Etching (Metal/Glass) | 10-30μm | ±5μm to ±15μm | 100:1 to 500:1 | 5-10 years | Industrial QC, robotics, general machine vision |

| Screen Printing (Paper/Plastic) | 50-100μm | ±50μm to ±100μm | 5:1 to 20:1 | 1-3 years | Education, rough positioning, non-critical applications |

| Inkjet Printing (Paper/Film) | 100-300μm | ±100μm to ±300μm | 10:1 to 50:1 | 1-2 years | Temporary use, visual reference only |

Key Insight: Photolithography delivers 10 to 50 times better edge sharpness and 20 to 100 times better dimensional accuracy compared to printing methods. This precision gap is why professional applications demand cleanroom-manufactured targets.

Industry Standards and Compliance

High-quality calibration targets adhere to recognized international standards:

ISO 12233:2017 – Photography – Electronic still picture imaging – Resolution and spatial frequency responses

- Defines eSFR (enhanced Slanted-Edge Spatial Frequency Response) test charts

- Specifies edge gradient requirements, contrast ratios, and measurement procedures

- Used globally for camera resolution and MTF testing

JB/T 9328-2024 – Resolution Test Charts Type A

- Chinese national industry standard for resolution targets

- Specifies dimensional tolerances, pattern layouts, and manufacturing requirements

- Widely adopted by Chinese camera and lens manufacturers

ISO 17025:2017 – General requirements for the competence of testing and calibration laboratories

- Ensures calibration certificates are traceable to national standards (NIST, PTB, NPL)

- Requires documented measurement uncertainty and traceability chain

- Essential for regulated industries (automotive, medical, aerospace)

Application-Specific Standards:

- Automotive: ISO 26262 (functional safety) requires calibration equipment accuracy ≤1/3 of device under test

- Aerospace: AS9100 quality management mandates documented metrology traceability

- Medical: FDA 21 CFR Part 820 requires calibrated equipment with documented accuracy

Cleanroom Manufacturing: The Precision Advantage

Why Cleanroom Environments Matter

Calibration target manufacturing requires particle-free environments to prevent contamination during critical fabrication steps. A single dust particle (5-10μm diameter) landing on the substrate during chrome coating or photoresist application can create defects that compromise pattern integrity.

Particle Contamination Effects:

- Pinholes in chrome layer: Localized areas where chrome fails to coat due to dust particle blocking deposition

- Edge irregularities: Particles trapped under photoresist cause uneven edge profiles during development

- Contrast reduction: Contamination scatters light, reducing effective contrast ratio

- Dimensional errors: Large particles (>20μm) distort pattern geometry

Cleanroom classification follows ISO 14644-1, which defines maximum allowable particle concentrations:

| Cleanroom Class | Particles/m³ (≥0.5μm) | Particles/ft³ (≥0.5μm) | Typical Applications |

|---|---|---|---|

| Class 100 (ISO 5) | 3,520 | 100 | Photolithography, semiconductor wafer processing |

| Class 1,000 (ISO 6) | 35,200 | 1,000 | Precision assembly, optical coating |

| Class 10,000 (ISO 7) | 352,000 | 10,000 | General manufacturing, electronics assembly |

| Conventional Factory | >35,000,000 | >1,000,000 | Non-critical manufacturing |

For comparison, typical outdoor air contains 35 million to 350 million particles per cubic meter—10,000× more than a Class 100 cleanroom.

Class 100 Photolithography Cleanroom

CalibVision’s photolithography process occurs in a Class 100 (ISO 5) cleanroom with <100 particles per cubic foot (≥0.5μm diameter). This semiconductor-grade environment ensures:

Ultra-Clean Chrome Coating

Chrome deposition via vacuum sputtering or evaporation requires particle-free conditions. Even a single 5μm dust particle creates a “shadow” where chrome fails to coat, resulting in a pinhole defect visible under magnification.

Class 100 environment reduces defect density from ~10-50 defects/cm² (conventional environment) to <0.1 defects/cm² (cleanroom), improving yield from ~60% to >95%.

Precision Photoresist Application

Photoresist—a light-sensitive polymer—is spin-coated onto the chrome layer to create a uniform film (typical thickness: 1-5μm). Particles trapped in the photoresist cause:

- Uneven film thickness (affects UV exposure consistency)

- “Comets” or streaks during spin coating

- Localized development defects

Cleanroom conditions ensure photoresist uniformity within ±2% across the entire substrate, critical for consistent pattern transfer.

Controlled UV Exposure and Development

After UV laser writing transfers the calibration pattern to the photoresist, chemical development removes exposed (or unexposed, depending on resist type) areas to reveal the pattern structure.

Temperature (23°C ±1°C), humidity (45% ±5% RH), and airborne molecular contamination must be tightly controlled during development to ensure:

- Consistent development rate across the substrate

- Sharp edge profiles (<1μm transition)

- No residual resist in cleared areas

Result: <1μm Feature Edge Sharpness

The combination of cleanroom manufacturing and photolithography process achieves feature edges sharper than 1 micrometer—comparable to semiconductor chip manufacturing. This precision is physically impossible with printing or conventional laser etching methods.

Class 1,000 Vacuum Lamination Room

For film-based calibration targets, CalibVision uses a Class 1,000 cleanroom for vacuum lamination—bonding precision-printed film to glass substrates.

Precision Film-to-Glass Bonding

The vacuum lamination process:

- Film and glass cleaned in cleanroom environment (removes particles >10μm)

- Optical adhesive applied (uniform thickness: 10-50μm)

- Film positioned on glass with ±0.1mm alignment accuracy

- Assembly placed in vacuum chamber (pressure reduced to <10 mbar)

- Vacuum eliminates air bubbles, ensuring bubble-free bonding

- UV or thermal curing solidifies adhesive

Eliminating Air Bubbles and Defects

Air bubbles trapped between film and glass cause:

- Localized optical distortion (refractive index mismatch)

- Pattern displacement (bubble elevates film locally)

- Reduced adhesion (bubble expands/contracts with temperature)

Class 1,000 cleanroom combined with vacuum lamination achieves <0.01% bubble defect rate (less than 1 bubble per 100cm² area) vs. 1-5% for conventional hand-lamination.

Ensuring Optical Clarity and Flatness

The lamination process must maintain:

- Optical transmission: >90% for glass substrate (bubbles/particles reduce transmission)

- Flatness: ±0.1mm across entire surface (critical for focus uniformity)

- Adhesion: No delamination over 3-5 year lifespan

Cleanroom environment prevents dust contamination that causes adhesion failures and optical defects.

Cleanroom vs. Conventional Manufacturing

| Factor | Class 100 Cleanroom | Class 1,000 Cleanroom | Conventional Factory |

|---|---|---|---|

| Particle Count (≥0.5μm) | <100 particles/ft³ | <1,000 particles/ft³ | >1,000,000 particles/ft³ |

| Defect Density | <0.1 defects/cm² | <1 defect/cm² | 10-50 defects/cm² |

| Edge Quality | <1μm edge sharpness | 5-10μm edge sharpness | 50-300μm edge sharpness |

| Production Yield | >95% first-pass yield | >90% first-pass yield | 50-70% first-pass yield |

| Lifespan (Indoor) | 10-15 years | 5-10 years | 1-3 years |

| Cost Premium | 3-5× base cost | 2-3× base cost | 1× (baseline) |

| Applications | Metrology, research, automotive ADAS | Industrial QC, robotics | Education, temporary use |

Key Takeaway: Cleanroom manufacturing costs 2-5× more than conventional methods but delivers 10-50× better precision and 3-10× longer lifespan. For professional applications requiring sub-pixel accuracy, cleanroom targets are the only viable option.

Chrome Coating Manufacturing Process: Eight Precision Steps

CalibVision’s photolithography process combines semiconductor-grade cleanroom manufacturing with precision laser writing to create calibration targets that meet the most demanding accuracy requirements. Each step is carefully controlled to ensure consistent, defect-free results.

Figure 1: CalibVision’s eight-step photolithography process delivers <1μm feature edge sharpness and >1000:1 contrast ratio—10 to 50 times more accurate than conventional printing or laser etching methods.

Step 1: Substrate Material Selection

We start with high-quality soda-lime glass or ceramic substrates to ensure stability and long-term precision.

The substrate is the foundation of every calibration target. Material selection directly impacts dimensional stability, optical quality, and lifespan.

Soda-Lime Glass Substrates (Standard Option)

- Composition: 70-75% SiO₂ (silica), 12-15% Na₂O (soda), 10-12% CaO (lime)

- Optical transmission: >90% at 550nm (visible light)

- Coefficient of thermal expansion (CTE): 9 ppm/°C

- Flatness: ±0.1mm across 500mm diagonal

- Cost: Moderate (60% of quartz glass cost)

- Best for: Professional applications in climate-controlled environments (15-30°C)

Quartz Glass Substrates (Premium Option)

- Composition: >99.9% SiO₂ (fused silica)

- Optical transmission: >95% at 550nm, extends to UV (200nm) and NIR (2500nm)

- Coefficient of thermal expansion: 0.5 ppm/°C (18× lower than soda-lime)

- Flatness: ±0.05mm across 500mm diagonal

- Cost: Premium (2.5× soda-lime glass cost)

- Best for: Metrology labs, temperature-varying environments, UV/IR applications

Ceramic Substrates (Specialized Option)

- Composition: Alumina (Al₂O₃) or silicon carbide (SiC)

- Advantages: Extremely low CTE (4-6 ppm/°C), high hardness (scratch-resistant)

- Disadvantages: Opaque (no transmitted light testing), higher cost

- Best for: Reflective-only calibration targets, extreme environments

Why Substrate Quality Matters

The substrate must provide:

- Dimensional Stability: Low thermal expansion prevents pattern distortion with temperature changes. A 1°C temperature variation causes a 500mm soda-lime glass substrate to expand/contract by 4.5μm—acceptable for ±5μm tolerance targets but problematic for ±1μm metrology-grade targets (hence quartz glass requirement).

- Optical Clarity: High light transmission (>90%) enables transmitted light calibration setups where the target is backlit. Optical-grade glass is free from inclusions, bubbles, or scratches that scatter light.

- Flatness: Non-flat substrates cause focus variations across the pattern. A 0.2mm elevation difference over 500mm creates ~0.2mm focus error at 1m working distance—unacceptable for high-resolution cameras with shallow depth of field.

Substrate Preparation

Before chrome coating, substrates undergo:

- Cutting (if custom size): Laser or diamond saw cutting to specified dimensions

- Edge polishing: Ground and polished edges (Ra <0.4μm) prevent micro-cracks

- Cleaning: Multi-stage ultrasonic cleaning in DI water + IPA, removing particles >1μm

- Inspection: Optical inspection for scratches, inclusions, flatness deviations

Only substrates passing inspection proceed to chrome coating.

Step 2: Laser Writing (Pattern Transfer)

The calibration pattern is written onto the coated chrome layer using a high-precision laser system for consistent accuracy.

Unlike traditional photolithography (which uses photomasks), CalibVision employs direct laser writing—a maskless process where a focused laser beam directly patterns the photoresist-coated substrate.

High-Precision Laser Writing System

- Laser type: Solid-state UV laser (355nm or 405nm wavelength)

- Spot size: 1-5μm diameter (determines minimum feature size)

- Positioning accuracy: ±0.5μm (±0.0005mm) via precision air-bearing stages

- Writing speed: 10-100 mm/s (depends on pattern complexity)

- Repeatability: <0.2μm positioning error between subsequent writes

Direct-Write Process onto Chrome-Coated Layer

The laser beam is raster-scanned or vector-traced across the photoresist surface, selectively exposing areas according to the calibration pattern design:

- CAD file input: Customer-provided or standard pattern (ChArUco, checkerboard, dot grid, ISO12233, USAF1951, custom)

- Pattern rasterization: Vector graphics converted to pixel grid matching laser spot size

- Laser exposure: Focused laser beam exposes photoresist, causing chemical change (positive resist: exposed area becomes soluble; negative resist: unexposed area becomes soluble)

- Real-time feedback: Laser power and focus continuously monitored/adjusted to maintain consistent exposure

Pattern Accuracy: Sub-Micron Positioning Control

The combination of:

- High-resolution laser spot (1-5μm)

- Precision motion stages (±0.5μm positioning)

- Real-time focus control (maintains spot size across non-flat substrates)

- Environmental control (temperature ±1°C prevents thermal expansion during write)

Results in pattern placement accuracy of ±1μm or better—critical for calibration targets where feature positions must match specified dimensions within micron-level tolerance.

Consistency: Automated Process Eliminates Human Error

Direct laser writing is fully automated:

- No manual alignment or positioning (unlike screen printing)

- No photomask handling (eliminates contact damage, contamination)

- Repeatable pattern generation (batch-to-batch consistency)

- Digital pattern library (instant changeover between designs)

This automation ensures every target of a given design is functionally identical, with feature positions matching within ±1μm across all units.

Compatible Patterns

CalibVision’s laser writing system supports:

- ChArUco boards: ArUco marker + checkerboard combination (robust corner detection)

- Checkerboard patterns: Classic camera calibration (OpenCV, MATLAB compatible)

- Dot grids: Circle centers for high-accuracy calibration

- AprilTags: Fiducial markers for robotics (precise 6DOF pose estimation)

- ISO 12233 eSFR: Resolution and MTF test charts

- USAF 1951: Classic resolution target

- Custom designs: Upload CAD file (DXF, GDSII, Gerber) for proprietary patterns

Step 3: Developing

The exposed areas are developed to reveal the pattern structure.

After laser writing, the photoresist must be chemically developed to selectively remove exposed (or unexposed, depending on resist type) regions, revealing the underlying chrome layer in the pattern areas.

Chemical Development Process

- Developer immersion: Substrate immersed in developer solution (typically alkaline for positive resists)

- Selective dissolution: Exposed photoresist dissolves; unexposed resist remains

- Development time: Tightly controlled (typically 60-120 seconds) for consistent results

- Rinse: DI water rinse stops development, removes residual chemicals

- Drying: Nitrogen blow-dry or spin-dry prevents water spotting

Process Variables Affecting Quality

- Developer concentration: Too strong → over-development (pattern features enlarge); too weak → under-development (incomplete clearing)

- Development time: Too long → undercutting (resist lifts at edges); too short → resist residue in cleared areas

- Temperature: ±1°C temperature control ensures consistent development rate

- Agitation: Gentle stirring ensures uniform developer concentration across substrate

Precision Timing for Consistent Results

Modern development systems use:

- Time-controlled immersion: Automated substrate handling, precise timing (±1 second accuracy)

- Temperature control: Developer bath maintained at 23°C ±0.5°C

- Fresh developer: Regular replenishment maintains consistent concentration

Result: Development uniformity within ±2% across entire substrate, ensuring consistent feature dimensions.

Pattern Verification

After development, substrates undergo optical inspection:

- Microscope examination (50-100× magnification): Verify complete resist removal in cleared areas, no residue

- Edge profile check: Confirm vertical (non-undercut) resist sidewalls

- Dimensional spot-check: Measure several features to confirm pattern accuracy before proceeding to etching

Substrates showing development defects are stripped (resist removed) and reprocessed.

Step 4: Etching

The chrome layer is etched to form clean, high-contrast features with sharp edges.

With the photoresist pattern developed, the underlying chrome layer is now selectively exposed. Chemical etching removes chrome from the exposed areas, transferring the photoresist pattern into the chrome layer.

Wet Chemical Etching Process

- Etchant composition: Ceric ammonium nitrate (CAN) or similar chrome etchant

- Immersion: Substrate immersed in etchant solution

- Chrome dissolution: Chemical reaction dissolves exposed chrome (areas not protected by photoresist)

- Etch rate: Typically 10-30nm/second (depends on chrome thickness, etchant strength, temperature)

- Endpoint detection: Visual or optical monitoring determines when chrome fully cleared

- Rinse: Thorough DI water rinse stops etching, removes residual chemicals

Result: Sharp Edges with <1μm Precision

Wet etching of thin chrome films (80-120nm thickness) produces extremely sharp edges because:

- Isotropic etching: Chrome etches equally in all directions, but thin film limits lateral etch to ~40-60nm (half the film thickness)

- Vertical sidewalls: Photoresist protects chrome beneath, creating near-vertical edge profile

- Minimal undercutting: Thin chrome + controlled etch time limits undercut to <100nm

Resulting edge sharpness: <1μm transition from chrome to glass—10 to 100× sharper than laser-etched or printed patterns.

Contrast Ratio: >1000:1 (Chrome vs. Glass)

Chrome coating provides:

- Reflectivity: 60-75% (bright chrome) or 6-30% (brown chrome) in visible spectrum

- Glass transmission: >90% in visible spectrum

- Effective contrast: >1000:1 in transmitted light setups (backlit target)

This high contrast ensures reliable corner detection across wide range of camera exposures and lighting conditions.

Edge Quality Superior to Printing or Laser Ablation

Comparison of edge sharpness (10% to 90% intensity transition distance):

- Photolithography chrome etching: <1μm

- Laser ablation (metal): 10-30μm (heat-affected zone broadens edge)

- Screen printing: 50-100μm (ink bleeds into substrate pores)

- Inkjet printing: 100-300μm (ink droplet spreading + substrate absorption)

Photolithography delivers 10 to 300× sharper edges, enabling sub-pixel corner localization (0.01-0.05 pixel accuracy) vs. 0.5-2 pixel accuracy for printed targets.

Step 5: Stripping & Cleaning

Residual photoresist and impurities are removed to achieve a smooth, flawless surface.

After etching, the photoresist has served its purpose and must be completely removed, leaving only the chrome pattern on glass substrate.

Multi-Stage Cleaning Process

Stage 1: Chemical Stripping

- Resist stripper immersion: Substrate immersed in solvent-based or alkaline stripper

- Photoresist dissolution: Stripper breaks down polymer bonds, dissolving photoresist

- Time: 5-15 minutes (depends on resist type, thickness)

- Complete removal: No photoresist residue remains on chrome or glass

Stage 2: Ultrasonic Cleaning

- Ultrasonic bath: Substrate placed in DI water + surfactant, subjected to ultrasonic agitation (40-80 kHz)

- Cavitation cleaning: Microscopic bubbles collapse at substrate surface, dislodging particles

- Duration: 5-10 minutes

- Effectiveness: Removes particles down to <1μm size

Stage 3: IPA Rinse and Drying

- Isopropyl alcohol (IPA) rinse: Final rinse in 99%+ pure IPA

- Water displacement: IPA displaces water, preventing water spots

- Rapid drying: IPA evaporates quickly, leaving no residue

- Nitrogen blow-dry (optional): Accelerates drying, ensures spot-free surface

Result: Smooth, Flawless Surface

Post-cleaning inspection verifies:

- No photoresist residue: Microscope examination at 100-200× magnification

- No particle contamination: Surface free from dust, fibers, chemical residues

- No water spots or stains: Optical clarity maintained

Only targets passing this inspection proceed to next stage.

Cleanroom Environment Prevents Recontamination

All cleaning steps occur in Class 1,000 or better cleanroom to prevent recontamination after cleaning. Particles settling on the substrate after final cleaning would compromise optical quality and dimensional accuracy.

Step 6: Checking & Repair

Each target is carefully inspected. Any defects are corrected to maintain micron-level accuracy.

Quality control at this stage catches manufacturing defects before targets proceed to final inspection and packaging.

Automated Optical Inspection (AOI)

High-resolution camera system scans entire target surface:

- Resolution: 5-10μm per pixel (sufficient to detect defects >10μm)

- Illumination: Bright-field and dark-field lighting to highlight different defect types

- Image processing: Automated defect detection algorithm identifies anomalies

- Throughput: 1-5 minutes per target (depends on size, pattern complexity)

Defect Types Checked

Pinholes or Voids in Chrome Layer

- Cause: Dust particle during chrome deposition or photoresist application

- Appearance: Small circular clear areas (typically 5-50μm diameter) in chrome regions

- Impact: Reduces contrast, creates false corners if in critical areas

- Detection: Bright-field illumination shows pinholes as bright spots in dark chrome areas

Edge Irregularities

- Cause: Photoresist development issues, non-uniform etching

- Appearance: Jagged or wavy edges instead of straight lines

- Impact: Degrades corner localization accuracy

- Detection: High-magnification inspection of critical edges (checkerboard corners, dot boundaries)

Dimensional Deviations

- Cause: Laser writing positioning errors, thermal expansion during processing

- Appearance: Features slightly larger/smaller or offset from specified positions

- Impact: Calibration errors if deviation exceeds tolerance (typically ±5μm for professional targets)

- Detection: Automated dimensional measurement of sample features, compared to CAD file

Surface Contamination

- Cause: Particles deposited during handling or processing

- Appearance: Small opaque spots or fibers on glass or chrome areas

- Impact: Optical quality reduction, potential false feature detection

- Detection: Dark-field illumination highlights particles as bright spots

Repair Process

Minor defects can be corrected:

Chrome Touch-Up (for small pinholes):

- Focused ion beam (FIB) or laser-induced chrome deposition

- Fills pinholes <20μm diameter

- Maintains pattern integrity

Edge Correction (for small irregularities):

- Localized re-etching or laser trimming

- Corrects edge deviations <5μm

Cleaning (for surface contamination):

- Localized cleaning with IPA + lint-free cloth

- Ultrasonic cleaning for stubborn particles

Reject Threshold

Targets with defects that cannot be economically repaired are rejected:

- Pinholes >20μm diameter in critical areas (corners, dot centers)

- Edge irregularities >5μm affecting corner detection

- Dimensional errors >10μm (exceeds typical ±5μm tolerance)

- Multiple defects (>5 per 100mm² area)

Reject rate for CalibVision’s cleanroom process: typically 3-8% (vs. 30-50% for non-cleanroom manufacturing).

Step 7: Pellicle Mounting (Optional)

A protective pellicle film can be added to prevent dust contamination, especially for demanding environments.

Pellicle mounting is an optional process that adds a transparent protective film elevated above the pattern surface, preventing dust contamination without affecting optical quality.

Purpose: Prevents Dust Contamination

Even in controlled environments, dust can settle on calibration target surfaces over time:

- Indoor lab: 1-5 particles (>10μm) per cm² per month

- Industrial environment: 10-50 particles per cm² per month

- Outdoor testing: 100+ particles per cm² per day

Dust particles on the pattern surface cause:

- Contrast reduction: Particles scatter light, reducing effective contrast

- False features: Large particles (>50μm) may be detected as pattern features

- Cleaning frequency: Requires frequent cleaning (risk of scratching)

Pellicle film prevents dust from reaching the pattern surface, extending maintenance intervals from weeks to months or years.

Pellicle Specifications

Optical-Grade Transparent Film

- Material: Stretched cellulose nitrate or fluoropolymer membrane

- Thickness: 0.5-2μm (extremely thin to minimize optical impact)

- Optical transmission: >95% (minimal light loss)

- Flatness: Tensioned membrane maintains flat profile

Elevated Above Pattern Surface

- Pellicle frame height: 3-10mm above pattern surface

- Purpose: Particles landing on pellicle are far out of focus, invisible to camera

- Result: Calibration camera focused on pattern (at substrate surface) does not resolve dust particles on pellicle surface

Mounting Process

- Pellicle frame (aluminum or plastic) precisely aligned to target edges

- Adhesive bonding or mechanical clamping secures frame to substrate

- Inspection: Verify pellicle tension (no wrinkles), cleanliness, optical quality

Applications: Outdoor Testing, Industrial Environments, Long-Term Deployment

Pellicle mounting recommended for:

- Outdoor testing: Prevents rain, dust, pollen from contaminating pattern

- Industrial environments: High airborne particle concentration (metalworking, construction sites)

- Autonomous vehicle testing: Targets mounted on test vehicles exposed to road dust

- Long-term installations: Permanent calibration targets in production facilities

Trade-Off: Slight Cost Increase vs. Extended Target Lifespan

Pellicle mounting adds:

- Cost: +15-25% of base target cost (pellicle frame, installation, inspection)

- Benefits:

- 5-10× longer maintenance intervals (cleaning frequency)

- Eliminates risk of cleaning-induced scratches

- Extends effective lifespan by 2-3× (pattern surface remains pristine)

For applications where target is difficult to access (high mounting, outdoor installation) or where downtime for cleaning is costly, pellicle mounting provides substantial long-term value.

Step 8: Quality Assurance & Certification

Every calibration target undergoes strict quality checks to ensure it meets industrial precision standards before shipment.

Final inspection is the last checkpoint before targets are approved for delivery. This comprehensive quality verification ensures customers receive targets that meet stated specifications.

Final Inspection Checklist

1. Dimensional Verification (2D/3D Metrology)

Targets measured using:

- 2D video measuring system: 0.1μm resolution, ±(2+L/200)μm accuracy per ISO 10360-2

- 3D coordinate measuring machine (CMM): ±1.5μm probe accuracy, non-contact optical probing

Measured parameters:

- Feature width/diameter (checkerboard squares, dot diameters)

- Feature spacing (center-to-center distance)

- Pattern alignment (orthogonality of rows/columns)

- Overall dimensions (target outer size)

Acceptance criteria: All dimensions within ±5μm (or tighter for metrology-grade targets) of CAD specifications.

2. Optical Quality Assessment

Contrast Ratio Measurement

- Spectrophotometer or calibrated camera measures intensity in chrome vs. glass regions

- Target: Contrast ratio >1000:1 for transmitted light, >100:1 for reflected light

- Verification: Measure at 5-9 points across pattern, confirm uniformity

Transmission/Reflectance Verification

- Glass regions: >90% transmission at 550nm (soda-lime), >95% (quartz)

- Chrome regions: Reflectivity matches specified chrome type (blue, brown, bright)

3. Edge Sharpness Measurement

Microscope Inspection (100-200× magnification)

- Visual examination of critical edges (checkerboard corners, dot boundaries)

- Verify: Clean, sharp edges with no ragged profiles, chipping, or irregularities

- Photographic documentation of representative edges

Optional: Quantitative edge measurement

- Knife-edge scan or interferometric measurement

- Measure 10%-90% intensity transition distance

- Target: <5μm for professional-grade, <1μm for metrology-grade

4. Flatness Verification

Substrate flatness measurement

- CMM or optical profilometer scans entire surface

- Target: ±0.1mm flatness over entire substrate (tighter for large-format targets)

- Impact: Non-flat substrates cause focus variations, degrading corner detection

5. Pattern Integrity Confirmation

Visual inspection (low magnification, full-field view)

- Verify: No missing features, no contamination, uniform appearance

- Check: Pellicle (if installed) is clean, properly tensioned, optically clear

Automated pattern recognition (optional):

- Camera captures pattern, computer vision algorithm detects all features

- Verify: Correct number of features detected, no false positives, consistent contrast

Documentation

Every target ships with:

Certificate of Conformity

- Target model, serial number, manufacturing date

- Measured dimensions (sample features)

- Dimensional tolerance confirmation (e.g., “All features within ±5μm of specification”)

- Optical quality confirmation (contrast ratio, transmission)

- Technician signature, QC manager approval

Optional: ISO 17025 Calibration Certificate (+$200, 1-week lead time)

- Full dimensional report (all features measured, not just samples)

- Measurement uncertainty budget per ISO GUM

- Traceability chain to NIST/PTB/NPL via accredited calibration lab

- Certificate number, accreditation details, expiration date

Handling and Storage Guidelines

- Recommended storage conditions (temperature, humidity)

- Cleaning procedures (IPA + lint-free cloth)

- Protective case usage instructions

Meets Industrial Precision Standards Before Shipment

Only targets passing all inspection criteria are approved for shipment. Targets failing any checkpoint are either:

- Reworked: Minor issues corrected (cleaning, edge touch-up)

- Downgraded: Sold as lower-grade product if still meets reduced specs

- Scrapped: Defects too severe to correct

This rigorous final inspection ensures customers receive targets that perform as specified, with documented verification of quality.

Protective Packaging: Flight Case with Foam Inserts

Approved targets are packaged in protective flight cases:

- Heavy-duty construction: Aluminum frame, reinforced corners, secure latches

- Custom foam inserts: Density 25kg/m³, cut to target size, prevents movement

- Protection level: Drop-tested to 1.2m, suitable for air freight

- Labeling: Target model, serial number, handling instructions

Flight case packaging ensures targets arrive undamaged, ready for immediate use.

Why This Process Delivers Superior Quality

Photolithography vs. Alternative Methods

The chrome coating photolithography process described above represents the gold standard for calibration target manufacturing. To understand why, let’s compare it to alternative methods:

| Quality Metric | Photolithography (Chrome on Glass) | Laser Etching (Metal/Glass) | Screen Printing (Paper/Plastic) | Inkjet Printing (Paper/Film) |

|---|---|---|---|---|

| Edge Sharpness | <1μm | 10-30μm | 50-100μm | 100-300μm |

| Dimensional Accuracy | ±0.5μm to ±2μm | ±5μm to ±15μm | ±50μm to ±100μm | ±100μm to ±300μm |

| Contrast Ratio | >1000:1 (transmitted light) | 100:1 to 500:1 (reflected) | 5:1 to 20:1 | 10:1 to 50:1 |

| Spatial Uniformity | <±1% across pattern | ±2% to ±5% | ±5% to ±10% (ink density varies) | ±10% to ±20% (droplet consistency) |

| Lifespan (Indoor) | 10-15 years | 5-10 years | 1-3 years (fading, warping) | 1-2 years (fading) |

| Manufacturing Environment | Class 100 cleanroom | Standard factory | Standard factory | Office environment |

| Substrate Options | Optical-grade glass (quartz, soda-lime) | Metal, glass, ceramic | Paper, plastic, fabric | Paper, film, vinyl |

| Typical Applications | Metrology labs, automotive ADAS, semiconductor inspection, research | Industrial QC, robotics, machine vision | Education, rough positioning | Temporary use, visual reference |

Key Insights:

- 10 to 300× Better Edge Sharpness: Photolithography’s <1μm edges enable sub-pixel corner localization (0.01-0.05 pixel accuracy). Printed targets’ 50-300μm fuzzy edges limit accuracy to 0.5-2 pixels—a 10 to 100× performance gap.

- 20 to 100× Better Dimensional Accuracy: Photolithography’s ±0.5-2μm tolerance ensures calibrated parameters match reality. Printed targets’ ±50-300μm errors propagate directly into calibration results, causing 1-5% systematic errors in focal length, distortion coefficients, and 3D reconstruction.

- 50 to 200× Higher Contrast: Photolithography’s >1000:1 contrast ensures reliable detection across varying lighting and camera settings. Printed targets’ 5:1 to 50:1 contrast requires controlled lighting, limits working distance, and increases false detection rates.

- 3 to 10× Longer Lifespan: Glass substrate + chrome coating maintains dimensional stability for 10-15 years. Printed targets warp, fade, and degrade within 1-3 years, requiring frequent replacement.

Cleanroom Environment Benefits

Manufacturing in Class 100 (photolithography) and Class 1,000 (lamination) cleanrooms provides:

Particle-Free Processing Prevents Defects

A single 10μm dust particle landing on the substrate during chrome coating creates a pinhole defect visible under magnification. Cleanroom environment reduces particle concentration by 10,000× (from >1 million particles/ft³ in conventional factory to <100 particles/ft³ in Class 100), cutting defect density from ~30 defects/cm² to <0.1 defects/cm².

Result: Production yield increases from ~60% (conventional) to >95% (cleanroom), reducing waste and ensuring consistent quality.

Consistent Results Batch-to-Batch

Cleanroom’s controlled temperature (±1°C), humidity (±5%), and airborne molecular contamination ensure:

- Chrome coating thickness uniform within ±10nm across substrate and between batches

- Photoresist development rate consistent (±2% variation), producing identical edge profiles

- Etching uniformity within ±3% across substrate

Result: Every target of a given design performs identically, with feature dimensions matching within ±1μm across all units.

Long-Term Dimensional Stability

Glass substrate manufactured and coated in cleanroom environment:

- Free from internal stress (would cause warping over time)

- Free from contaminants that degrade chrome adhesion

- Chemically stable (no oxidation or corrosion)

Result: Targets maintain dimensional accuracy within ±0.1% over 10+ years, even under environmental stress (temperature cycling, humidity variations).

Multi-Stage Inspection Ensures Reliability

CalibVision’s six inspection checkpoints (materials analysis, AOI, precision measurement, image testing, calibration validation, final documentation) ensure defects are caught and corrected during manufacturing, not discovered by the customer after delivery.

Defects Caught and Corrected During Manufacturing

- Checkpoint 1 (Materials): Reject substrates with flatness, transmission, or contamination issues before processing begins

- Checkpoint 2 (AOI after etching): Identify pinholes, edge irregularities, dimensional deviations while repair is still possible

- Checkpoint 3 (Precision measurement): Verify feature dimensions match specifications within tolerance

- Checkpoint 4 (Image testing): Validate pattern performance with actual cameras and calibration algorithms

- Checkpoint 5 (Calibration validation): Confirm targets deliver specified calibration accuracy (e.g., <0.1 pixel RMS error)

- Checkpoint 6 (Final documentation): Document all measurements, create traceability records

Final Product Meets Stated Specifications

By the time a target ships, it has passed six independent quality verifications. Customer receives:

- Target with documented dimensional accuracy (measurement data included)

- Verified optical quality (contrast ratio, transmission measured)

- Tested performance (validated with cameras and calibration software)

- Traceable certification (ISO 17025 certificate optional)

Confidence in Results: Customers can trust that calibration parameters derived from CalibVision targets accurately represent their camera/lens system, not artifacts of target manufacturing errors.

Traceability and Documentation for Compliance

Regulated industries (automotive, medical, aerospace) require documented traceability of calibration equipment to national standards:

- Automotive (ISO 26262): Calibration equipment must have documented accuracy ≤1/3 of device under test, with traceability to recognized standards

- Medical (FDA 21 CFR Part 820): Calibration equipment requires certificates traceable to NIST or equivalent

- Aerospace (AS9100): Quality management system demands documented metrology traceability

CalibVision’s documentation (certificate of conformity, optional ISO 17025 certificate) provides required traceability, satisfying regulatory requirements and enabling customers to pass audits.

Material Selection: Why Substrate Quality Matters

The substrate—the base material onto which the calibration pattern is applied—fundamentally determines a target’s dimensional stability, optical quality, and lifespan. Professional applications demand substrates that maintain accuracy over years of use, across varying environmental conditions.

Glass Substrates (Quartz vs. Soda-Lime)

Glass is the preferred substrate for high-precision calibration targets due to its exceptional dimensional stability, optical clarity, and long-term durability.

Optical Transmission (>90-95%)

Glass substrates enable transmitted light calibration—a setup where the target is backlit from behind, and the camera images the illuminated pattern. This configuration offers several advantages:

- Uniform illumination: Backlight provides consistent, diffuse illumination across entire pattern (eliminates shadows, hotspots from reflective lighting)

- High contrast: Transmitted light through glass (bright) vs. chrome coating (opaque) creates >1000:1 contrast

- Reduced glare: No specular reflections from target surface (common issue with reflective targets)

- Depth of field: Transmitted light targets have no surface texture to cause focus variations

For transmitted light to work effectively, the glass substrate must transmit >90% of incident light:

- Soda-lime glass: >90% transmission at 550nm (visible spectrum)

- Quartz glass: >95% transmission, extends from UV (200nm) to NIR (2500nm)

This high transmission ensures maximum signal reaches the camera sensor, enabling low-light calibration and reducing exposure time.

Dimensional Stability (Low Thermal Expansion)

A calibration target’s specified dimensions (e.g., 30.00mm square spacing) must remain constant over time and temperature. Glass substrates achieve this through extremely low thermal expansion:

Soda-Lime Glass:

- CTE (Coefficient of Thermal Expansion): 9 ppm/°C (parts per million per degree Celsius)

- Example: A 500mm target expands by 4.5μm per 1°C temperature increase

- Impact: ±10°C temperature variation → ±45μm dimensional change

- Suitable for: Climate-controlled environments (20°C ±5°C typical)

Quartz Glass (Fused Silica):

- CTE: 0.5 ppm/°C (18× lower than soda-lime glass)

- Example: A 500mm target expands by only 0.25μm per 1°C

- Impact: ±10°C temperature variation → ±2.5μm dimensional change

- Suitable for: Temperature-varying environments (-20°C to +200°C)

Why Low CTE Matters:

If your ±5μm tolerance calibration target is used at 30°C (measured/certified at 20°C), a 10°C temperature difference causes:

- Soda-lime glass (CTE 9 ppm/°C): 45μm expansion in 500mm dimension → exceeds tolerance by 9×

- Quartz glass (CTE 0.5 ppm/°C): 2.5μm expansion → remains within tolerance

For metrology-grade applications (±1μm tolerance), quartz glass is mandatory. For professional applications in controlled environments, soda-lime glass provides adequate stability at lower cost.

Flatness (±0.1mm Across Entire Surface)

Non-flat substrates cause focus variations across the calibration pattern. If one corner of the target is 0.5mm elevated relative to the opposite corner:

- At 1m working distance: 0.5mm elevation causes ~0.5mm focus error

- For a camera with 50mm focal length, f/2.8 aperture: depth of field ≈ ±1mm

- Result: Corners at different elevations appear sharp or blurred depending on focus position

This focus variation degrades corner detection accuracy:

- Sharp corners: Sub-pixel localization (<0.05 pixel error)

- Slightly defocused corners: 0.1-0.3 pixel error

- Significantly defocused corners: 0.5-2 pixel error or detection failure

Professional calibration targets specify flatness tolerance:

- Standard grade: ±0.2mm across 500mm diagonal

- Professional grade: ±0.1mm across 500mm diagonal

- Metrology grade: ±0.05mm across 500mm diagonal

Glass substrates, unlike paper or plastic, maintain flatness over time (no warping from humidity, temperature cycles).

Long-Term Durability (10+ Years)

Glass substrates resist environmental degradation:

Chemical stability:

- Inert to most chemicals (acids, solvents, cleaning agents)

- No oxidation or corrosion

- Resistant to UV exposure (no yellowing or opacity increase)

Mechanical durability:

- Scratch-resistant (Mohs hardness 5-7)

- High tensile strength (does not crack under normal handling)

- Does not deform under stress (unlike plastics)

Environmental resistance:

- Unaffected by humidity (no swelling/shrinkage like paper/wood)

- Temperature stable (no creep or relaxation like polymers)

- Insect/mold resistant (unlike organic materials)

Expected lifespan:

- Indoor, controlled environment: 15-20 years with minimal degradation

- Indoor, uncontrolled environment: 10-15 years

- Outdoor with protective pellicle: 5-10 years

- Outdoor without protection: 3-5 years (UV and rain degrade chrome coating)

Soda-Lime Glass vs. Quartz Glass: Selection Guide

| Factor | Soda-Lime Glass | Quartz Glass (Fused Silica) |

|---|---|---|

| Cost | Baseline (1.0×) | 2.5-3× soda-lime cost |

| Optical Transmission | >90% (visible) | >95% (UV to NIR, 200-2500nm) |

| Thermal Expansion (CTE) | 9 ppm/°C | 0.5 ppm/°C (18× lower) |

| Flatness | ±0.1mm (λ/4 @ 633nm) | ±0.05mm (λ/10 @ 633nm) |

| Temperature Range | Best: 15-30°C<br>Acceptable: 0-50°C | -20°C to +200°C |

| UV Transmission | Blocks <350nm | Transmits from 200nm (deep UV) |

| IR Transmission | Attenuates >2000nm | Transmits to 2500nm (SWIR) |

| Typical Applications | • Professional QC<br>• Indoor robotics<br>• Machine vision<br>• Automotive (controlled temp) | • Metrology labs<br>• Research institutions<br>• Outdoor testing<br>• UV/IR calibration<br>• Extreme environments |

| Recommendation | Best value for 80% of professional applications<br>Controlled indoor environments (HVAC-equipped labs, production facilities) | Essential for demanding applications<br>Temperature variations, metrology-grade accuracy, UV/IR spectrum |

Decision Framework:

- Choose soda-lime glass if: Climate-controlled environment (±5°C typical), visible spectrum (400-700nm), professional accuracy (±2-5μm), cost-sensitive

- Choose quartz glass if: Temperature varies >10°C, UV/IR spectrum required, metrology-grade accuracy (±0.5-1μm), maximum stability needed

Optical Film Substrates

For applications requiring lightweight, flexible, or cost-effective calibration targets, optical film substrates offer an alternative to glass.

Flexibility and Lightweight Advantages

Film substrates (polyester, polycarbonate, acetate):

- Thickness: 0.1-0.5mm (vs. 1.6mm glass)

- Weight: 0.1-0.3 kg/m² (vs. 4-6 kg/m² for glass)

- Flexibility: Can be rolled for transport (glass must be handled flat)

Applications benefiting from film:

- Portable calibration: Fieldwork, drone calibration, outdoor testing (lightweight reduces transport burden)

- Large-format targets: Film targets >1m² are easier to handle than equivalent glass (weight, fragility concerns)

- Temporary installations: Short-term testing, trade shows, demonstrations

Transmission Characteristics

Film substrates provide:

- Transparency: 85-92% transmission (visible spectrum)

- Slight haze: 2-5% diffuse transmission (vs. <0.5% for optical glass)

- Wavelength-dependent: Polyester yellows with UV exposure, reducing blue/UV transmission over time

Result: Film targets work well for transmitted light calibration but have slightly lower optical quality than glass (reduced contrast due to haze, potential color shifts).

Application Limitations

Film substrates compromise on several quality parameters:

Dimensional stability:

- Thermal expansion: 50-150 ppm/°C (10-30× higher than glass)

- Humidity sensitivity: ±0.2-0.5% dimensional change with humidity (glass: negligible)

- Example: 500mm film target expands by 25-75μm per 1°C (vs. 4.5μm for soda-lime glass, 0.25μm for quartz)

Flatness:

- Film naturally curls/waves (requires tensioning or lamination to glass for flatness)

- Even when laminated, film-on-glass targets exhibit ±0.2-0.5mm flatness (vs. ±0.1mm for chrome-on-glass)

Lifespan:

- Indoor: 3-5 years before yellowing, warping, or delamination becomes noticeable

- Outdoor: 1-2 years (UV exposure accelerates degradation)

- Vs. glass: 1/3 to 1/5 the lifespan

Mechanical durability:

- Scratches easily (pencil hardness 2-3H vs. 5-7H for glass)

- Tears under stress (cannot handle rough handling)

- Requires protective case for transport

Recommendation: Use film targets for temporary, portable, or large-format applications where weight/flexibility is critical. For permanent installations or long-term accuracy, glass substrates are superior.

Coating Technologies

The coating material determines pattern contrast, reflectivity characteristics, and wavelength response.

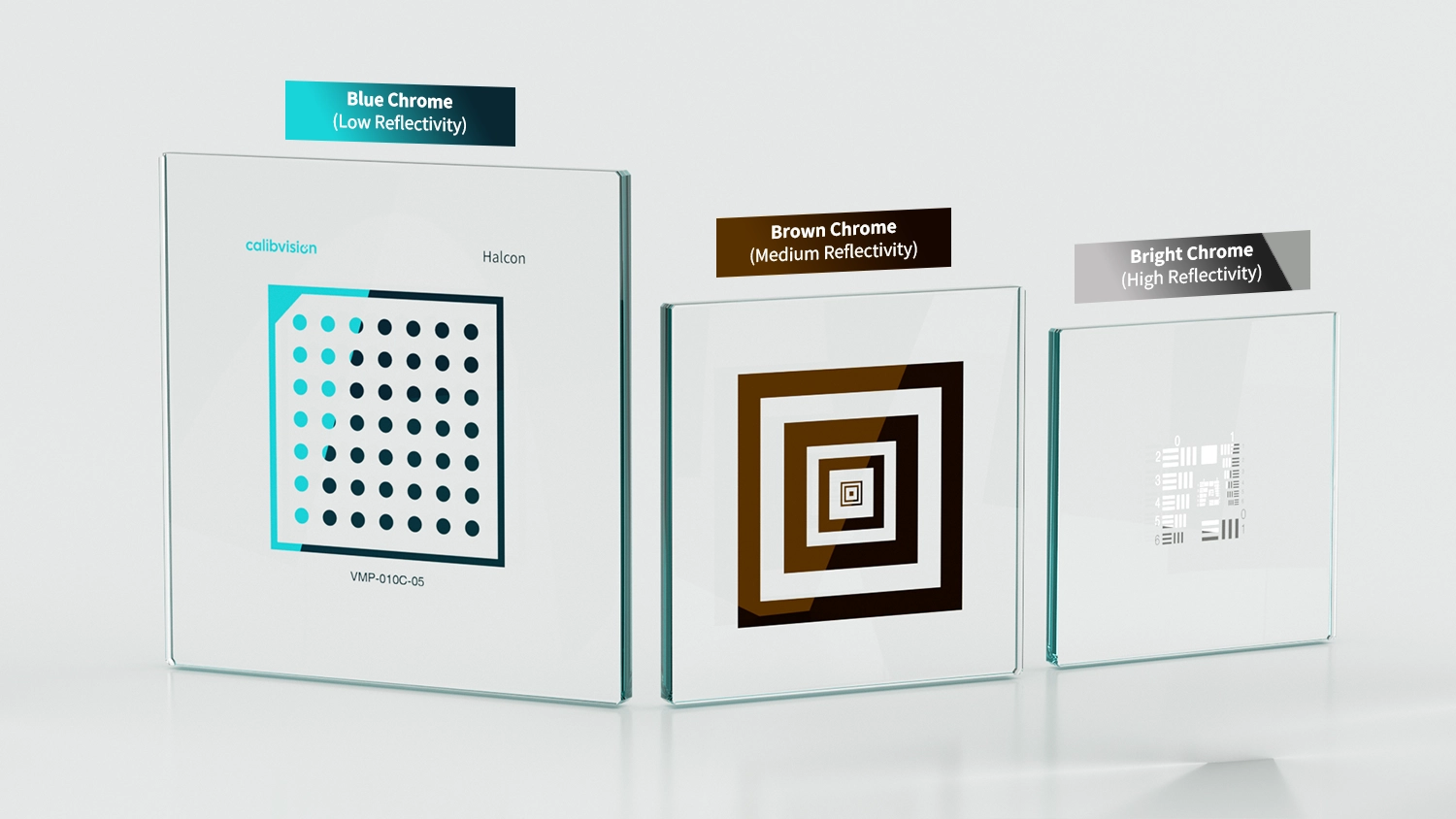

Chrome Coating (Blue, Brown, Bright)

Chrome is the industry-standard coating for photolithography calibration targets due to:

- High contrast: Opaque chrome (blocks >99.9% of light) vs. transparent glass (transmits >90%)

- Durability: Chrome forms stable oxide layer, resists corrosion and scratching

- Manufacturing compatibility: Well-established photolithography processes

Three chrome types differ in spectral reflectivity:

Blue Chrome:

- Reflectivity: 5-20% (visible), wavelength-dependent (higher at blue end, drops toward red/IR)

- Appearance: Blue-gray metallic

- Best for: Applications requiring low reflectivity or wavelength-specific characteristics

- Limitation: Variable reflectivity across spectrum (not ideal for multi-spectral imaging)

Brown Chrome:

- Reflectivity: 6-30% (visible to NIR), relatively flat across wavelengths

- Appearance: Bronze/brown metallic

- Best for: Multi-spectral applications (RGB + NIR cameras), consistent performance across wavelengths

- Advantage: Stable mid-range reflectivity provides optimal contrast without saturation risk

Bright Chrome:

- Reflectivity: 60-75% (visible)

- Appearance: Mirror-like silver finish

- Best for: High-contrast resolution test charts (MTF, USAF1951), reflected light calibration

- Limitation: High reflectivity risks saturation in well-lit environments or high camera gain

Selection Guide:

- Camera calibration targets (checkerboards, dot grids, ChArUco): Brown chrome (consistent wavelength response)

- Resolution test charts (ISO12233, USAF1951): Bright chrome (maximum contrast)

- Specialized applications (UV/IR, low-light): Blue chrome (tailored reflectivity)

Spectral Reflectivity Characteristics

Chrome coating’s reflectivity varies with wavelength, affecting performance across different camera types:

Brown Chrome (CalibVision’s standard for calibration targets):

- 440-550nm (blue-green): 6-8% reflectivity

- 550-700nm (green-red): 20-28% reflectivity

- 700-1040nm (NIR): 28-32% reflectivity

Key advantage: Relatively flat response across visible and NIR spectrum ensures consistent contrast for RGB cameras, monochrome sensors, and NIR imaging systems. This consistency is critical for multi-camera systems using different sensor types.

Bright Chrome:

- 440-1040nm: 60-75% reflectivity, slightly increasing toward longer wavelengths

- Use case: Maximum contrast for high-resolution imaging, but high reflectivity risks glare/saturation

Blue Chrome:

- 440-540nm: 15-22% reflectivity (peak in blue region)

- 700-1040nm: 2-8% reflectivity (drops significantly in NIR)

- Use case: Specialized applications requiring blue-wavelength selective response

Contrast Optimization for Different Wavelengths

Optimal chrome type depends on camera spectral response:

RGB Cameras (Bayer filter, 400-700nm):

- Recommended: Brown chrome (consistent 6-30% across RGB channels)

- Result: Uniform corner detection performance regardless of color channel

Monochrome Cameras (full spectrum, 400-1000nm):

- Recommended: Brown chrome (broad spectral coverage)

- Result: Works across entire sensor sensitivity range

NIR Cameras (700-1000nm):

- Recommended: Brown chrome (28-32% in NIR region)

- Avoid: Blue chrome (<8% in NIR, poor contrast)

UV Cameras (200-400nm):

- Recommended: Specialized UV-reflective coatings (chrome has poor UV response)

- Alternative: Quartz glass substrate with aluminum coating

Application-Specific Quality Requirements

Different industries and applications demand varying levels of calibration target accuracy. Understanding your application’s requirements helps select the appropriate target quality grade and manufacturing method.

Automotive ADAS & Autonomous Vehicles

ISO 26262 Functional Safety Requirements

Automotive Advanced Driver Assistance Systems (ADAS) and autonomous vehicle cameras are safety-critical components. ISO 26262 (Road vehicles – Functional safety) classifies them as ASIL-B to ASIL-D (Automotive Safety Integrity Level), depending on function:

- ASIL-B: Lane departure warning, traffic sign recognition

- ASIL-C: Adaptive cruise control, automatic emergency braking

- ASIL-D: Autonomous driving (Level 3-5 automation)

ISO 26262 requires calibration equipment accuracy ≤ 1/3 of device under test tolerance. For automotive cameras:

- Camera positioning accuracy requirement: Typically ±2mm at 10m distance (±0.02% error)

- Calibration target accuracy requirement: ≤±0.67mm (1/3 of camera requirement) → ≈±5μm in target feature dimensions

Conclusion: Automotive ADAS calibration demands professional-grade photolithography targets (±2-5μm accuracy). Printed targets (±50-300μm) fail to meet ISO 26262 requirements by 10-100×.

Multi-Camera System Calibration

Modern vehicles employ 4-12 cameras for 360° surround view, requiring:

- Extrinsic calibration: Camera-to-camera relative positioning (rotation, translation)

- Accuracy requirement: <1° angular error, <5mm translation error (for seamless image stitching)

- Target requirement: Large-format targets (1-2m) with ±5μm feature accuracy across entire pattern

Challenge: Large targets (>1m) magnify manufacturing errors. A ±50μm printing error becomes ±0.05mm → 1% error in 5mm measurement → unacceptable for surround view stitching.

Outdoor Environmental Stability

ADAS calibration often occurs outdoors (parking lots, test tracks) with:

- Temperature range: -10°C to +50°C (60°C range)

- Humidity: 20-90% RH

- UV exposure: Direct sunlight (accelerates degradation)

Target requirements:

- Dimensional stability: <0.05% change over temperature range → quartz glass (CTE 0.5 ppm/°C) recommended

- Protective pellicle: Prevents dust contamination during outdoor use

- Durable coating: Chrome coating resists UV fading (vs. printed patterns that fade within months)

Required Accuracy: ±2μm Typical

To meet ISO 26262’s 1/3 rule for ASIL-C/D systems:

- Device under test: ±5mm at 10m → ±0.05% accuracy

- Calibration target: ±1.67mm at 10m → ±0.017% accuracy

- Feature-level accuracy: 30mm feature → ±5μm tolerance

- Best practice: ±2μm target accuracy provides margin

Only photolithography chrome-on-glass targets meet this requirement.

Semiconductor & Electronics Inspection

Sub-Micron Positioning Requirements

Semiconductor wafer inspection and electronics PCB assembly use high-magnification cameras (10-100× magnification) to inspect:

- Semiconductor: Bond pads (50-200μm), die alignment (±2μm tolerance)

- PCB assembly: SMT component placement (0201 components: 0.6×0.3mm, ±50μm placement tolerance)

Camera calibration requirements:

- Pixel size: 2-5μm (typical for inspection cameras)

- Sub-pixel accuracy target: 0.01-0.05 pixel → 20nm-250nm positioning accuracy

- Calibration target requirement: Feature edge sharpness <1μm, dimensional accuracy ±0.5-1μm

Example calculation:

- Camera: 2.4μm pixel, requires 0.02-pixel accuracy → 48nm positioning accuracy

- Target feature: 1mm checkerboard square

- Allowable target error: <48nm (0.048μm) → practically impossible

- Solution: Target accuracy ±1μm with sub-pixel corner detection algorithms (Gaussian interpolation, moment-based refinement) achieve 0.02-pixel localization despite 1μm target tolerance

High-Magnification Microscopy Calibration

Microscope calibration for semiconductor/biology applications:

- Magnification: 50-1000× (1000× → 1mm field of view)

- Resolution: 0.2-1μm (limited by optical diffraction)

- Calibration target: USAF1951 resolution target or custom microscale patterns

Requirements:

- Feature size: Down to 0.5μm (Group 9, Element 6 of USAF1951)

- Manufacturing method: Only photolithography achieves <1μm feature edges

- Substrate: Quartz glass for UV microscopy, soda-lime for visible

Required Accuracy: ±0.5-1μm

Metrology-grade applications demand tightest tolerances:

- Feature dimensions: ±0.5μm (quartz glass substrate)

- Edge sharpness: <0.5μm (photolithography)

- Flatness: ±0.05mm (λ/10 at 633nm)

Only premium photolithography on quartz glass meets these requirements.

Robotics & Machine Vision

Hand-Eye Calibration Precision

Industrial robots use cameras mounted on the arm (eye-in-hand) or fixed to workspace (eye-to-hand). Hand-eye calibration determines the transformation between camera and robot coordinate frames.

Typical accuracy requirements:

- Robotic assembly: ±0.5mm positioning accuracy

- Pick-and-place: ±0.1-0.2mm accuracy for small components

- Bin picking: ±1-2mm accuracy (less critical)

Calibration target selection:

- Assembly/pick-and-place: ±5μm target accuracy (professional-grade photolithography)

- Bin picking: ±15μm target accuracy (laser-etched acceptable)

Repeatability Requirements

Robot vision systems require calibration repeatability: ability to achieve same calibration parameters when process is repeated.

Factors affecting repeatability:

- Target dimensional consistency: ±1μm variation between features → ±1μm variation in calibration

- Feature detection consistency: Sharp edges (<1μm) → 0.01-pixel detection repeatability; fuzzy edges (50-100μm) → 0.5-pixel repeatability

Result: Photolithography targets deliver 10-50× better calibration repeatability than printed targets.

Required Accuracy: ±5-15μm

Machine vision applications (QC inspection, measurement, guidance):

- ±5μm targets: High-precision applications (sub-millimeter positioning)

- ±10μm targets: Standard applications (millimeter-level positioning)

- ±15μm targets: Rough positioning, non-critical applications

Laser-etched targets (±10-15μm) acceptable for standard applications; photolithography (±2-5μm) required for precision work.

Medical Imaging Systems

FDA Compliance and Traceability

Medical diagnostic imaging devices (endoscopes, surgical cameras, radiography, ultrasound) are Class II or III medical devices regulated by FDA under 21 CFR Part 820 (Quality System Regulation).

Requirements:

- Calibration equipment traceability: Documented calibration chain to NIST or equivalent national metrology institute

- Calibration interval: 12-24 months re-certification

- Accuracy documentation: Measurement uncertainty stated per ISO GUM

Calibration targets for medical imaging:

- ISO 17025 accredited certificate: Mandatory for FDA compliance

- Dimensional accuracy: ±2-5μm (ensures diagnostic image geometry is accurate)

- Traceability: NIST-traceable dimensional measurements

Diagnostic Accuracy Requirements

Medical imaging calibration affects diagnostic decisions:

- Surgical navigation: 3D reconstruction accuracy directly impacts surgical precision (±1mm error → instrument positioning error)

- Tumor measurement: Calibrated cameras measure lesion size (diagnostic criterion for cancer staging)

- Retinal imaging: Fundus camera calibration ensures accurate retinal disease diagnosis

Consequence of calibration error: Misdiagnosis, incorrect treatment, patient harm.

Regulatory requirement: Medical device manufacturers must validate their calibration process with traceable reference standards → demands highest-quality calibration targets with documented accuracy.

Required Accuracy: ±2-5μm

Medical applications demand professional-grade targets:

- Photolithography on glass: ±2-5μm accuracy

- ISO 17025 certification: Traceable to NIST

- Regular re-certification: 12-24 month intervals

Aerospace & Defense

AS9100 Quality Standards

Aerospace industry follows AS9100 (Quality Management Systems for Aviation, Space, and Defense) which mandates:

- Calibration equipment traceability: Documented chain to national/international standards

- Calibration intervals: Strictly enforced (typically 12 months for critical measurements)

- Measurement uncertainty: Calculated per ISO GUM, documented

AS9100D Section 7.1.5.2:

“Where measurement traceability is a requirement, or considered by the organization to be an essential part of providing confidence in the validity of measurement results, measuring equipment shall be calibrated or verified at specified intervals, or prior to use, against measurement standards traceable to international or national measurement standards.”

Calibration targets for aerospace:

- ±1-2μm dimensional accuracy: Metrology-grade photolithography

- ISO 17025 certification: Mandatory

- Controlled environment storage: Prevents degradation

Mission-Critical Reliability

Aerospace applications (satellite imaging, aircraft landing systems, UAV navigation) are mission-critical:

- Satellite imaging: Calibration error → incorrect geolocation of imagery (intelligence failure, mission compromise)

- Aircraft landing systems: Vision-based landing aid calibration error → unsafe approach angles

- UAV navigation: Vision-based SLAM (Simultaneous Localization and Mapping) calibration error → navigation failure, loss of UAV

Consequence of calibration failure: Mission failure, loss of multi-million dollar asset, potential loss of life.

Requirement: Zero-defect calibration → highest-quality targets with full traceability and documentation.

Required Accuracy: ±1-2μm

Aerospace demands metrology-grade targets:

- Quartz glass substrate: Maximum thermal stability

- Photolithography: <1μm edge sharpness, ±1μm dimensional accuracy

- ISO 17025 certification: Full traceability to NIST/PTB

- Protective storage: Maintain accuracy over asset’s operational life (10-30 years for satellites)

Research & Metrology Labs

NIST/PTB Traceability Requirements

National metrology institutes (NIST in USA, PTB in Germany, NPL in UK) and accredited calibration labs operate under ISO 17025 (General requirements for competence of testing and calibration laboratories).

Requirements:

- Reference standards: Traceable to SI units (International System of Units)

- Measurement uncertainty: Calculated per ISO GUM (Guide to the Expression of Uncertainty in Measurement)

- Traceability chain: Documented from working standard → reference standard → national/international standard

Calibration targets for metrology labs:

- Primary reference standards: ±0.5μm accuracy, full uncertainty budget

- Working standards: ±1-2μm accuracy, ISO 17025 certified

- Regular re-certification: 12-24 months

Scientific Publication Standards

Peer-reviewed scientific research requires:

- Measurement uncertainty: All measurements reported with uncertainty (e.g., “30.00 ± 0.002 mm”)

- Traceability: Calibration equipment traceable to national standards

- Reproducibility: Independent labs must be able to replicate results

Example: Computer vision research paper reports camera calibration accuracy “0.05 pixel RMS reprojection error.” Reviewers expect:

- Calibration target specifications (dimensional accuracy, traceability)

- Calibration procedure documented

- Uncertainty analysis

If target dimensional accuracy is not documented/traceable → paper lacks reproducibility → may be rejected by reviewers.

Required Accuracy: ±0.5-1μm

Research/metrology demands highest-grade targets:

- Quartz glass substrate: Maximum stability (CTE 0.5 ppm/°C)

- Photolithography: <1μm edge sharpness, ±0.5μm dimensional accuracy

- ISO 17025 certification with full uncertainty budget: Traceable to NIST/PTB/NPL

- Controlled storage: Climate-controlled (<±1°C temperature, <±5% humidity)

How to Evaluate Calibration Target Quality

When selecting a calibration target supplier, it’s critical to verify that their manufacturing standards and quality control match your application requirements. This section provides practical guidance on evaluating target quality before purchasing.

Key Specifications to Verify

Feature Edge Sharpness (Ask for Microscope Images)

Edge sharpness is the single most important quality parameter for calibration accuracy. Request 100-200× magnification microscope images of:

- Checkerboard corner intersections

- Dot boundary edges

- Pattern feature edges

What to look for:

Excellent quality (photolithography):

- Clean, sharp edge transition

- No visible edge roughness or irregularities

- Edge appears as a crisp line even at 200× magnification

Poor quality (printed):

- Fuzzy or jagged edges

- Visible ink bleeding or halftone dots (screen printing)

- Edge appears as a gradual gradient, not a line

Quantitative measurement: If supplier provides edge profile data, look for:

- <5μm edge transition (10% to 90% intensity): Professional-grade

- 10-30μm: Laser-etched (acceptable for non-critical applications)

- >50μm: Printed (not suitable for sub-pixel calibration)

If supplier cannot provide microscope images → red flag indicating low-quality manufacturing.

Dimensional Accuracy (Request Measurement Data)

Supplier should provide actual measured dimensions, not just nominal specifications.

What to request:

- Measurement report: Sample features measured (e.g., 10 checkerboard squares, 20 dot diameters)

- Measurement method: How dimensions were measured (CMM, video measuring system, optical profilometer)

- Measurement uncertainty: Per ISO GUM (e.g., “30.00 mm ± 0.005 mm, k=2”)

What to look for:

- Consistent dimensions: All measured features within ±5μm (professional-grade) or ±2μm (metrology-grade)

- Documented measurement: Actual data, not generic spec sheet

- Traceable equipment: Measuring equipment calibrated/traceable to national standards

Warning signs:

- Supplier provides only nominal dimensions (“30.00 mm squares”) without actual measurements

- No measurement uncertainty stated

- Cannot explain measurement method

Manufacturing Method (Photolithography vs. Printing)

Directly ask supplier: “What manufacturing method do you use?”

Acceptable answers:

- “Photolithography with chrome-on-glass” → Professional-grade manufacturing

- “Laser etching on metal/glass” → Acceptable for mid-grade applications

- “High-resolution printing on [substrate]” → Consumer-grade (not suitable for professional use)

Red flags:

- Vague answers: “Advanced printing technology,” “Precision manufacturing” (without specifics)

- Refusal to disclose method

- Defensive responses when questioned

Follow-up question: “Do you manufacture in a cleanroom environment?”

- Yes, Class 100/1,000 cleanroom → Professional manufacturing

- No / unclear → Conventional factory (compromised quality)

Substrate Material and Thickness

Verify substrate specifications:

Material:

- Glass (soda-lime or quartz): Professional-grade, dimensional stability

- Film/plastic: Lightweight applications only (compromised stability)

- Paper: Not suitable for professional use (warping, humidity sensitivity)

Thickness:

- 1.5-2.0mm glass: Standard professional thickness

- <1.0mm glass: Fragile, may break during handling

- Film (<0.5mm): Flexible substrates (limited applications)

Transmission (for transmitted light targets):

- >90% at 550nm: Acceptable

- >95% at 550nm: Excellent (quartz glass)

- <85%: Poor optical quality or contamination

Calibration Certificate Traceability

Certificate of Conformity (included with professional targets):

- Target model, serial number, date

- Dimensional verification statement (“All features within ±5μm of specification”)

- Technician signature

ISO 17025 Calibration Certificate (optional, +$200-300):

- Full dimensional measurement report (all features measured)

- Measurement uncertainty budget

- Traceability statement: “Traceable to NIST via [accredited lab name], certificate #[number]”

- Accreditation body logo (NVLAP, A2LA, UKAS, DAkkS, etc.)

- Certificate validity period (typically 12-24 months)

How to verify ISO 17025 certificate authenticity:

- Check accreditation body website (NVLAP, A2LA, UKAS, etc.)

- Search for listed calibration lab

- Verify scope of accreditation includes dimensional calibration

- Certificate number should be in lab’s database

Red flags:

- “ISO 17025 compliant” without actual certificate (meaningless claim)

- Certificate from unknown/unaccredited lab

- No measurement uncertainty stated

- Generic certificate (not specific to your target’s serial number)

Red Flags: Signs of Low-Quality Targets

Fuzzy or Irregular Edges Under Magnification

When examining microscope images (or inspecting target in person with magnifying glass):

Red flags:

- Edges appear as gradual gradients (50-100μm transition) instead of sharp lines

- Jagged or wavy edges (sign of poor screen printing or laser etching)

- Visible halftone dots (screen printing process visible)

- Ink bleeding or color variations along edges