About Us

About Calibvision

What's the role of CalibVision in the machine vision industry?

We are known for delivering precision where it matters most—solving calibration accuracy and repeatability challenges that directly impact product quality—and establishing ourselves as one of the world leaders in sub-micron calibration standards and rapid custom solutions.

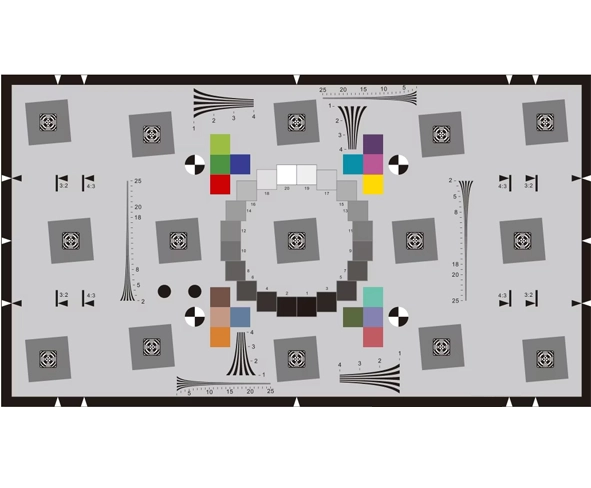

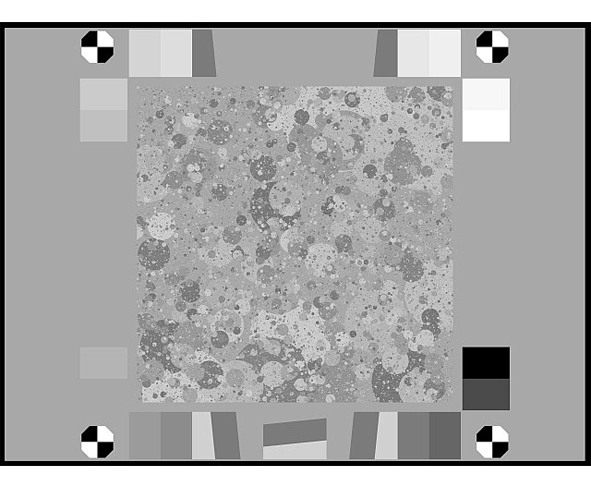

Today our product range encompasses all the precision references needed to ensure machine vision system accuracy: Photolithography Targets (0.3-1μm), ISO Standard Charts, Application-Specific Patterns, and Technical Consulting.

Today our product range encompasses all the precision references needed to ensure machine vision system accuracy: Photolithography Targets (0.3-1μm), ISO Standard Charts, Application-Specific Patterns, and Technical Consulting.

0.5μm

Precision Achieved

500+

Custom Solutions

72 Hours

Sample Delivery

50+

Global Customers

Testimonials

"CalibVision isn't just a supplier—they're a calibration partner who understands our testing challenges as well as we do."

"The precision and stability of their glass targets eliminated variables we were fighting with film-based charts for years."

"72-hour custom target delivery? We thought it was impossible until CalibVision proved otherwise."

"72-hour custom target delivery? We thought it was impossible until CalibVision proved otherwise."

Customer Success Stories

Trusted by Industry Leaders

Our calibration standards have been validated in some of the most demanding applications in machine vision. Here’s how we’ve helped customers achieve breakthrough results.

Our calibration standards have been validated in some of the most demanding applications in machine vision. Here’s how we’ve helped customers achieve breakthrough results.

Case Study 1

Smartphone Camera Module Testing

Challenge: A leading smartphone manufacturer needed to test 500,000+ camera modules per month with <1μm focus accuracy requirements.

Solution: CalibVision designed a custom 200×200mm glass target with 0.5μm precision, paired with automated testing integration support.

Result:

- 40% reduction in calibration time per module

- 99.8% pass rate improvement in final quality control

- Scalable solution deployed across 3 manufacturing sites

Case Study 2

Automotive ADAS Calibration

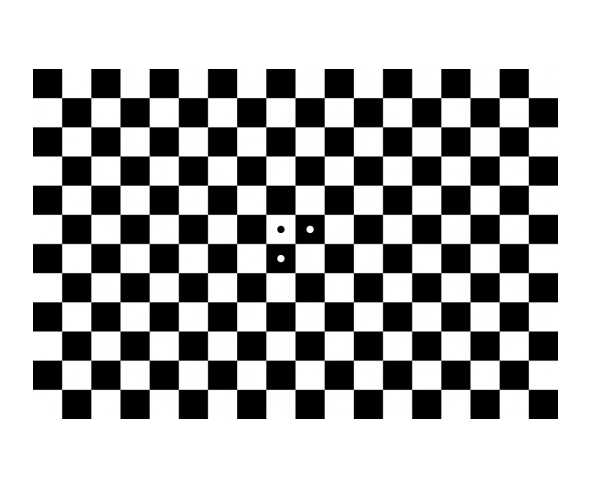

Challenge: An automotive Tier-1 supplier required large-format targets for calibrating 190° ultra-wide-angle cameras in parking assist systems.

Solution: 1200×1200mm aluminum oxide target with custom distortion grid, optimized for outdoor testing conditions.

Result:

- ±0.5° calibration accuracy across full field of view

- UV-resistant coating enabled 5+ year outdoor durability

- Adopted as standard across client's global production lines

Case Study 3

Medical Endoscope Calibration

Challenge: A medical device company needed IR-compatible targets for calibrating next-generation endoscope cameras with sub-1mm spatial resolution.

Solution: Custom quartz substrate targets with NIR-optimized coatings and micro-pattern features.

Result:

- FDA-compliant calibration documentation

- 30% improvement in edge detection accuracy

- Enabled product launch 2 months ahead of schedule

Meet the Team

CalibVision was founded by a team of optical engineers and machine vision specialists who’ve spent their careers at the intersection of imaging science and manufacturing excellence

Dr. Ben Tsang,

Founder & CTO

PhD in Optical Engineering

15+ years in precision optics manufacturing

Mr. Hua,

Head of Custom Solutions

MS in Mechatronics

200+ calibration systems

designed

designed

Mr. Liu, Quality &

Compliance Director

ISO auditor certified | 10+ years in optical metrology | Ensures every target meets international standards

Subscribe to Our Newsletter

*Subscribe to our newslatter to receive early disccount offers, updates and new products info.