Why Calibration Target Quality Matters: Manufacturing Standards That Ensure Accuracy

Introduction In the world of precision optical measurement, the calibration target is the foundation upon which all accuracy depends. Whether you’re calibrating cameras for autonomous vehicles, setting up stereo vision systems for robotics, or conducting research in machine vision, the quality of your calibration target directly determines the reliability of your results. Yet not all […]

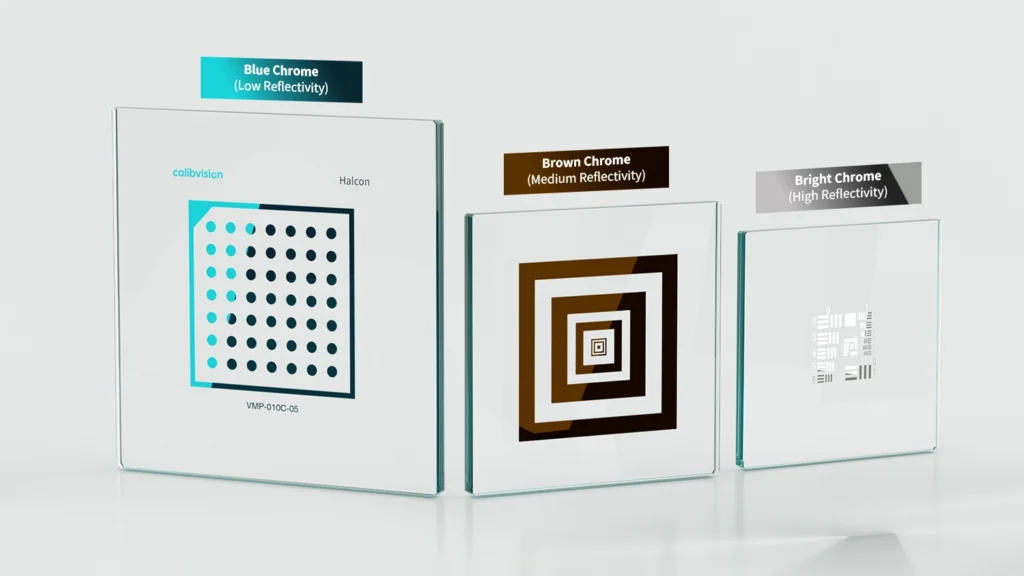

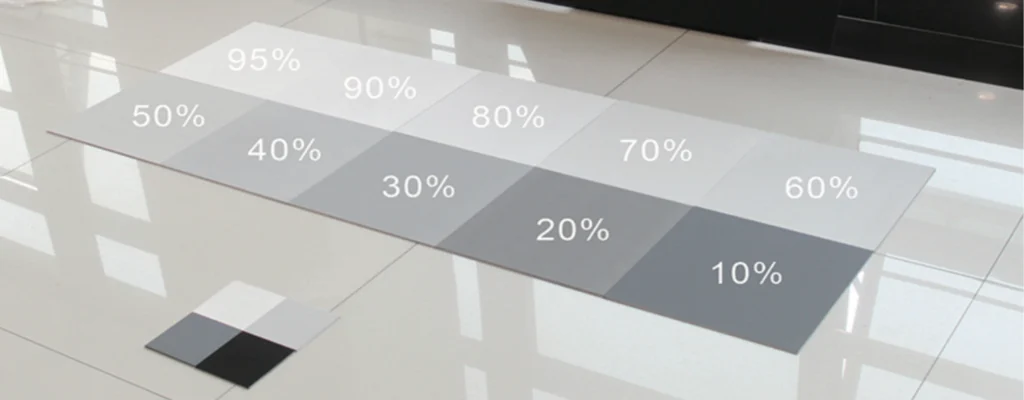

Diffuse Reflectance Standards for LiDAR and Camera Calibration: Complete Selection Guide

When it comes to calibrating optical measurement systems—from LiDAR sensors in autonomous vehicles to quality control cameras in manufacturing—precision matters. That’s where diffuse reflectance standards come in. These calibration targets provide the reference points that ensure your optical systems measure light accurately and consistently. What Are Diffuse Reflectance Standards? Diffuse reflectance standards are precision-engineered surfaces […]

Diffuse Reflectance Standards FAQ: 20 Expert Answers to Common Questions

Last Updated: January 2025 | Reading Time: 16 minutes Introduction “Can I use a photography gray card to calibrate my $100,000 LiDAR sensor?” This question—asked by an engineer at a major automotive supplier in 2023—led to three months of invalid testing, a delayed product launch, and $2.3 million in re-work costs. The answer? Absolutely not. […]

5 Industries Revolutionized by Precision Diffuse Reflectance Standards

Last Updated: January 2025 | Reading Time: 13 minutes Introduction In a Tesla factory in Fremont, California, a robotic vision system inspects battery cells at a rate of 120 per minute. Each cell must be classified by surface condition—detecting micro-scratches, discoloration, or contamination that could indicate manufacturing defects. The difference between accepting a defective cell […]

Why Manufacturing Quality Matters: Cleanroom Photolithography vs Conventional Reflectance Targets

Last Updated: January 2025 | Reading Time: 11 minutes Introduction Two reflectance standards sit side by side on a lab bench. Both claim “50% reflectance at 905nm.” Both look identical to the naked eye—matte gray surfaces, similar size, similar price point. You pick one, calibrate your $100,000 automotive LiDAR, collect three months of validation data, […]

How to Choose Diffuse Reflectance Standards: 7 Critical Specifications to Consider

Last Updated: January 2025 | Reading Time: 14 minutes Introduction You’re about to spend $500 to $15,000 on diffuse reflectance standards for your LiDAR or optical testing project. Make the wrong choice, and you’ll face: Make the right choice, and you’ll have: The difference? Understanding seven critical specifications that separate professional-grade reflectance standards from inadequate […]

LiDAR Calibration Guide: How to Use Diffuse Reflectance Standards for Automotive Testing

Last Updated: January 2025 | Reading Time: 15 minutes Introduction A Tesla Model S traveling at 120 km/h on the highway relies on its LiDAR sensor to detect a stopped vehicle 200 meters ahead. The sensor must accurately measure both distance (is the obstacle 200m or 205m away?) and reflectance (is it a dark-painted car […]

Understanding Lambertian Reflectance: The Science Behind Diffuse Reflectance Standards

Last Updated: January 2025 | Reading Time: 12 minutes Introduction When you shine a flashlight at a mirror, the reflected beam bounces back at a precise angle—miss that angle by a degree, and you see nothing. Point the same flashlight at a white wall, and it illuminates the entire room regardless of where you stand. […]