Diamond Cutting Lenses: Positioning vs Precision Measurement

This comprehensive guide explores the critical role of FA (Factory Automation) and telecentric lenses in modern diamond cutting operations. The article distinguishes between two essential optical applications: FA lenses for positioning and workflow management, and telecentric lenses for precision measurement and cutting guidance.

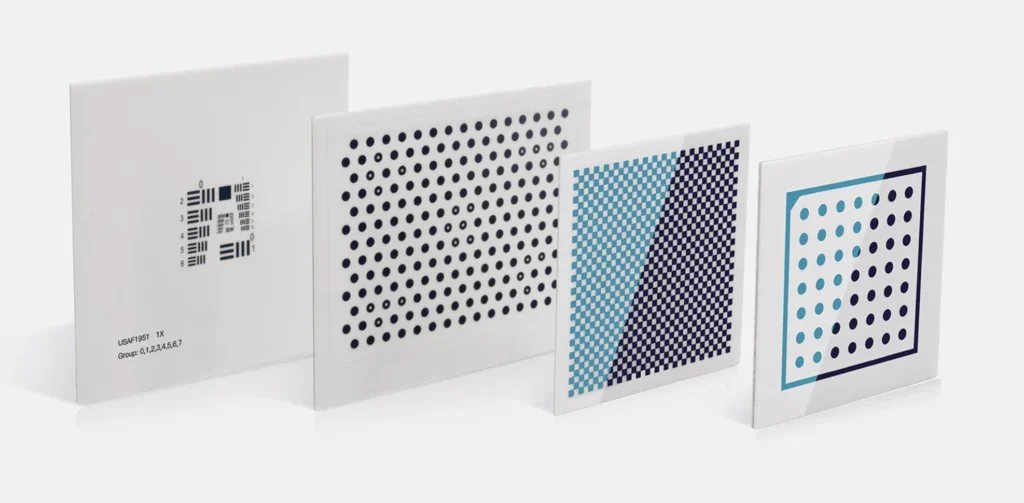

What Are Custom Test Targets? Complete Guide for Imaging Systems

Custom test targets are specialized charts designed for specific imaging applications to evaluate performance or calibrate settings. They measure resolution, distortion, color accuracy, and other parameters. Unlike standard targets, custom designs match exact application requirements, materials, and environmental conditions for more accurate system validation.

GIGE vs. USB3 Camera Cables: Which is Best for Your Vision System?

GigE Vision offers 1 Gbps speed with 100m cable reach, ideal for multi-camera industrial systems. USB3 Vision provides 5 Gbps speed but limits cables to 5m, best for single-camera high-speed applications. Choice depends on camera count, distance, environment, and scalability needs.

Machine Vision Cable Failures: Prevention & Troubleshooting Guide

Machine vision cables fail at the worst possible times. I’ve seen production lines shut down for hours because a $50 cable broke, costing companies thousands in lost productivity and missed deadlines. The good news? Most cable failures are completely preventable when you know what to look for and how to protect your systems. What Causes […]

Custom Calibration Targets for Dispensing Equipment: Complete Guide & Case Study

Custom calibration targets are precision reference patterns that help dispensing equipment maintain accuracy. Using quartz glass and laser writing technology, these targets achieve sub-5 micrometer precision across meter-scale areas, essential for electronics, automotive, and medical manufacturing quality control.

Best Cables for Machine Vision in Automotive Manufacturing

Automotive vision systems require specialized cables for each production zone: weld-resistant cables for body shops, chemical-resistant jackets for paint inspection, oil-proof designs for powertrain assembly, and high-flex cables for final quality control—all engineered to withstand 24/7 production demands.

How to Choose the Right Camera Cable for Machine Vision Systems

Selecting the right vision system cable requires evaluating interface type (GigE, USB3, Camera Link), mechanical requirements (flex needs, environment), electrical specifications (shielding, length), cable quality (connectors, construction), and application context to ensure reliable performance and future flexibility.

Ultimate Guide to High-Flex GigE Vision Cables: What Makes Them Different?

High-flex GigE Vision cables feature finely stranded conductors, specialized PUR/TPE jackets, and enhanced shielding to withstand millions of flex cycles in industrial environments. Unlike standard Ethernet cables, they maintain signal integrity during continuous movement in machine vision applications.