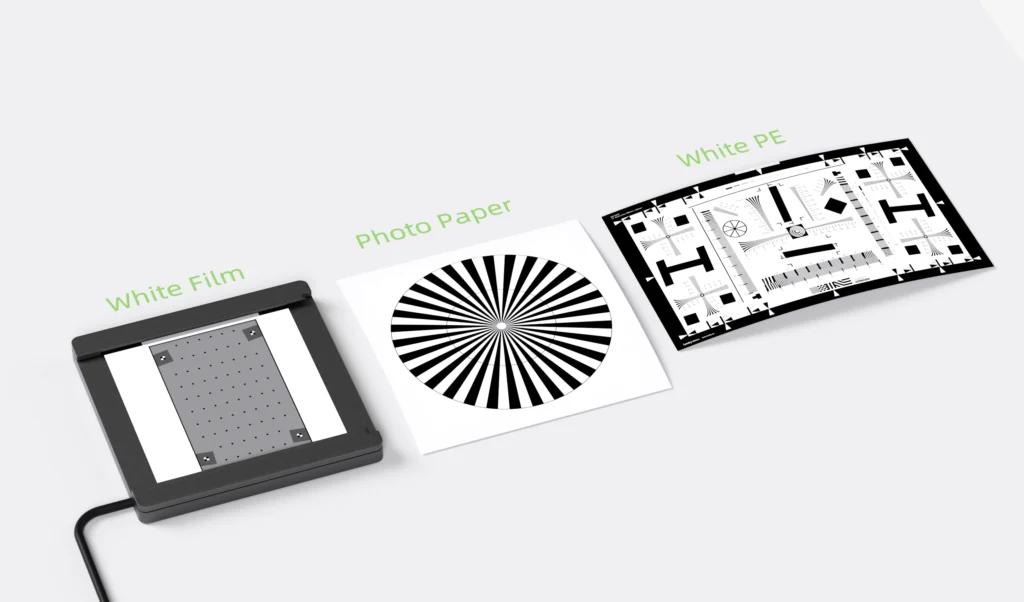

Which Calibration Chart Material Is Best? PE vs Film vs Paper

White PE calibration charts offer 30μm precision and industrial durability with front lighting. White Film provides 0.3mm resolution with backlight compatibility. Photo Paper delivers color accuracy for controlled environments. Each material has specific advantages for different imaging applications.

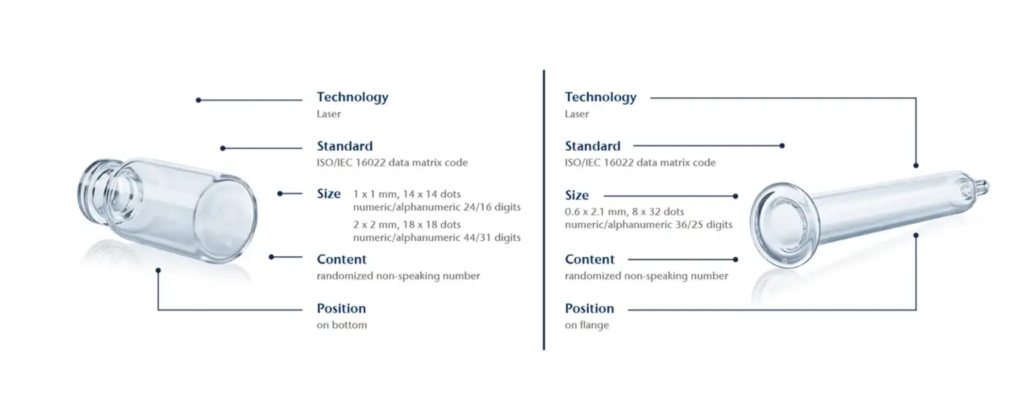

What Is AOI For Pharmaceutical Ampoule Inspection?

Automated Optical Inspection (AOI) for pharmaceutical ampoules uses specialized cameras, lighting, and software to detect critical defects including dimensions, wall thickness, cracks, contamination, and print quality at production speeds of up to 400 units per minute with 98-99% accuracy.

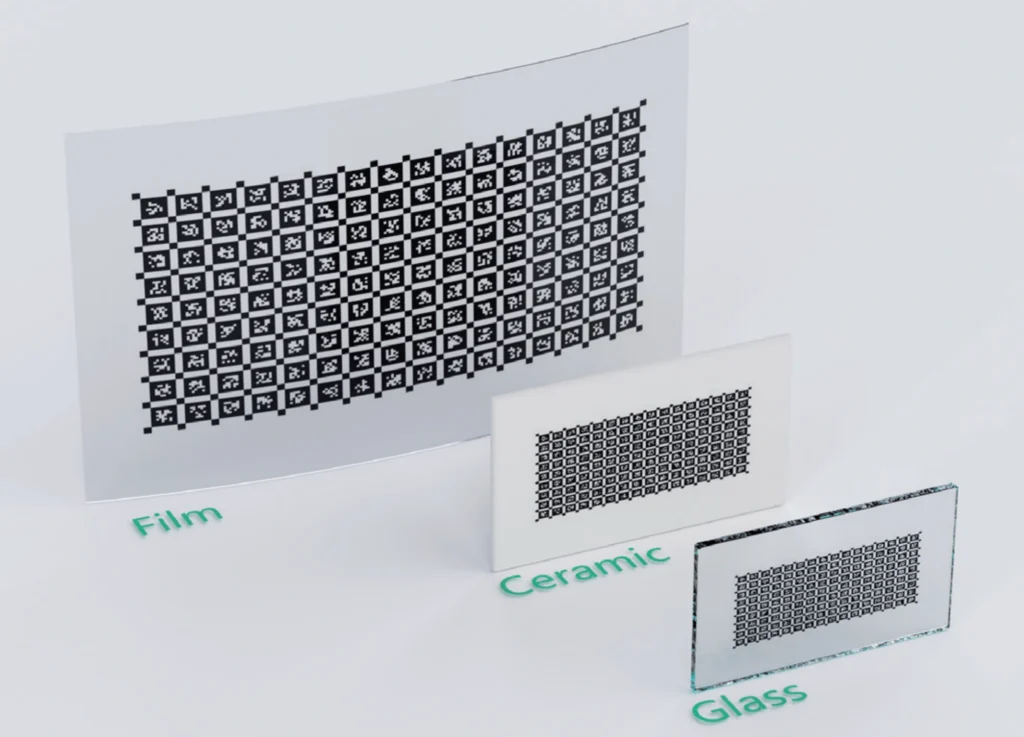

What Are Kalibr/AprilGrid Test Targets? Complete Guide

Kalibr/AprilGrid test targets use AprilTag coded markers for accurate multi-camera and IMU calibration. Available in glass (±1μm accuracy), ceramic (±2μm), and film (±15μm) substrates with various tag sizes and matrices, they enable robust calibration even with partially visible corners.

The Game-Changing Portable Demo Kit Every Machine Vision Professional Needs

The VisionLabHub Mini Demo Kit solves the machine vision industry’s demonstration challenge by providing a complete, portable system for showcasing cameras, lighting, test targets, and optics anywhere. This carry-on sized solution enables spontaneous demos worldwide, dramatically improving sales effectiveness.

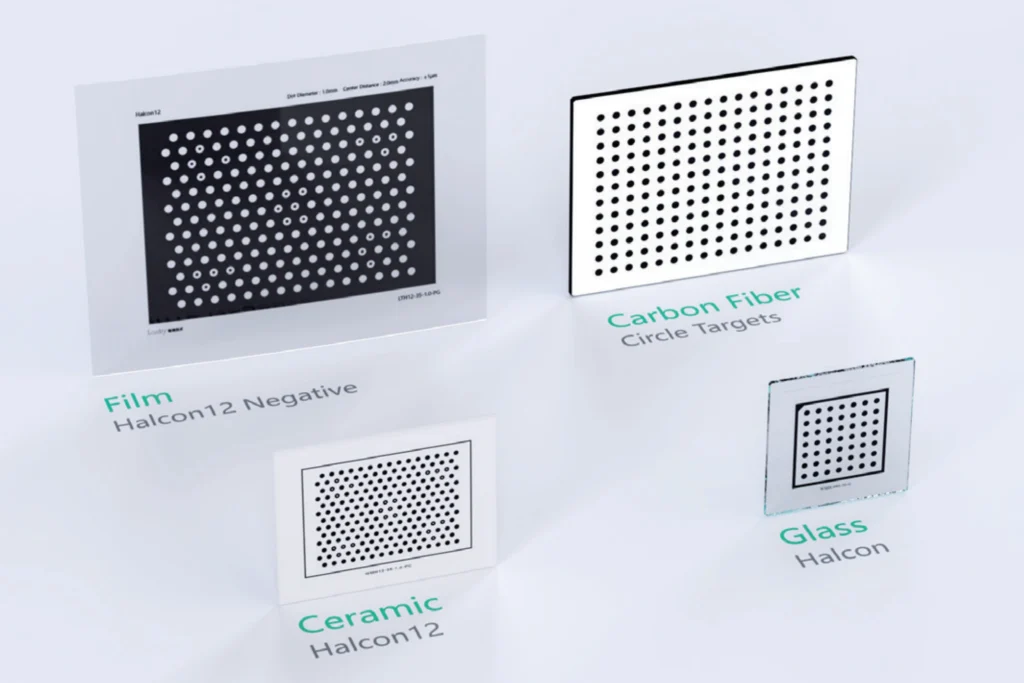

What Are Halcon Test Targets And How Do They Work?

Halcon test targets are precision calibration tools for machine vision systems featuring specific patterns of circles arranged in geometric configurations. Available in various materials (glass, ceramic, film) with different circle diameters (0.1mm-10mm) and accuracy levels (±1μm-±2μm).

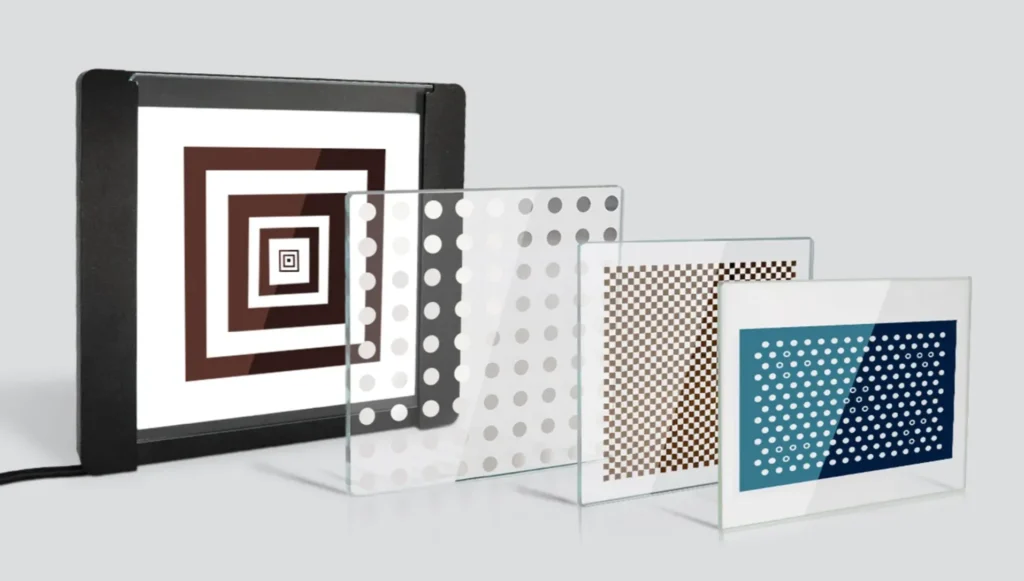

The Ultimate Imaging Test Device: How One Small Box Replaces An Entire Test Lab

This revolutionary imaging test device combines a light box, test charts, and an automated relay lens system to create a complete camera testing lab in a compact package. It tests MTF, color, and grayscale with precision while saving 95% in space and 70% in costs.

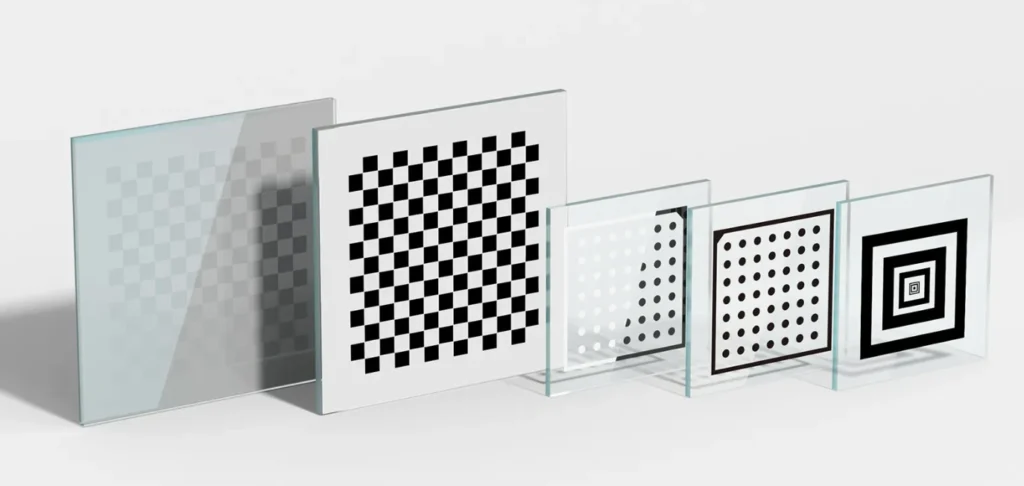

How to Customize a Calibration Target: The Complete Guide

This guide explains how to customize calibration targets by selecting appropriate manufacturing processes based on required precision (from 0.7μm to 0.3mm), choosing optimal materials, specifying custom shapes via laser cutting, and adding special features like backlights or mounting frames.

How to Select the Right Substrate Material for Calibration Targets: A Complete Guide

This guide explains how to select the ideal substrate material for calibration targets. Learn about opaque substrates (ceramic, paper, PE on glass) for front lighting and transparent options (soda lime glass, quartz glass, film) for back lighting, plus considerations for accuracy and environment.