What is a Halcon Calibration Target?

Halcon calibration targets are precisely manufactured physical objects with known geometric properties that serve as reference patterns for camera and machine vision system calibration. These specialized targets enable Halcon software to determine critical camera parameters including focal length, lens distortion, and spatial positioning, transforming standard cameras into accurate measurement instruments.

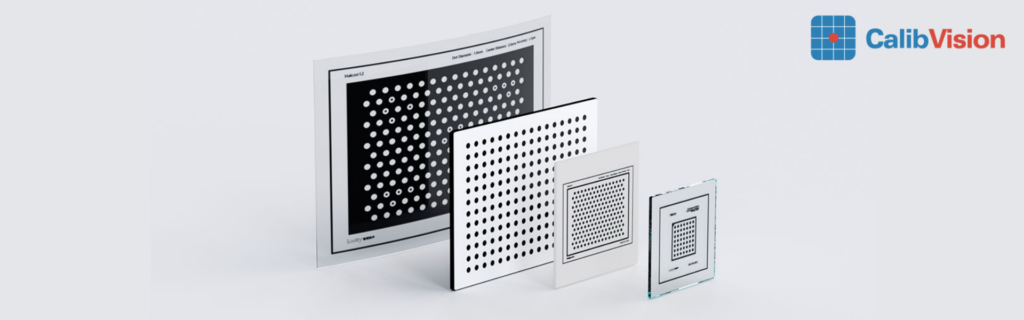

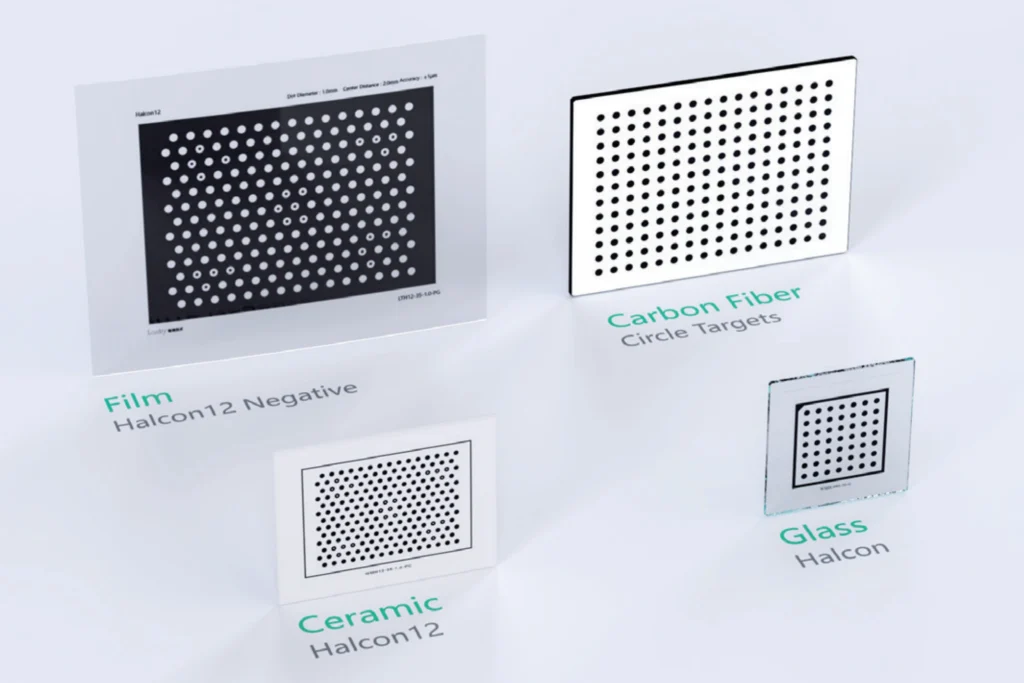

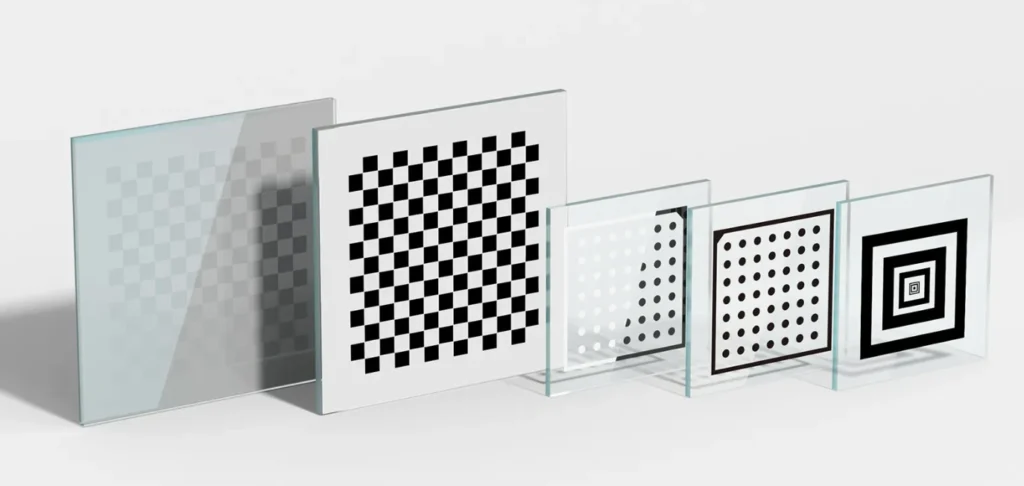

The calibration process involves capturing multiple images of the target from various angles and positions, allowing Halcon’s algorithms to analyze the known patterns and calculate precise camera parameters. Common target types include circular dot arrays, checkerboard patterns, and hexagonal arrangements, with customization options available through Halcon’s create_caltab operator.

These targets are essential for applications requiring high-precision measurements, including quality control inspection, robot guidance, 3D scanning, and dimensional analysis. By providing sub-pixel accuracy and correcting lens distortion effects, Halcon calibration targets enable reliable and consistent results across different operational conditions.

The proper selection and implementation of calibration targets significantly impact system performance, with factors such as working distance, accuracy requirements, environmental conditions, and target material playing crucial roles in achieving optimal calibration results. Professional implementation typically involves capturing 10-20 calibration images with the target filling approximately one-third to two-thirds of the camera’s field of view for maximum effectiveness.

Understanding Calibration Target Accuracy in Simple Terms

What is calibration target accuracy? When we talk about calibration target accuracy, we’re really asking one basic question: “How perfect is this pattern?” Just like when you buy a ruler, you want to make sure the measurements are correct. A calibration target works the same way – it needs to be extremely precise for your […]

Custom Calibration Targets for Dispensing Equipment: Complete Guide & Case Study

Custom calibration targets are precision reference patterns that help dispensing equipment maintain accuracy. Using quartz glass and laser writing technology, these targets achieve sub-5 micrometer precision across meter-scale areas, essential for electronics, automotive, and medical manufacturing quality control.

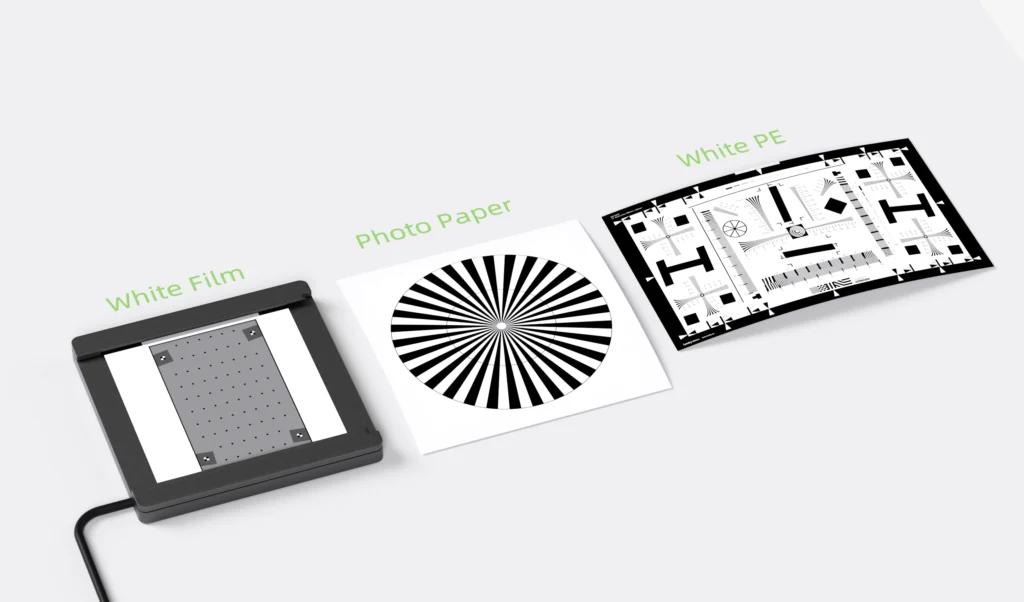

Which Calibration Chart Material Is Best? PE vs Film vs Paper

White PE calibration charts offer 30μm precision and industrial durability with front lighting. White Film provides 0.3mm resolution with backlight compatibility. Photo Paper delivers color accuracy for controlled environments. Each material has specific advantages for different imaging applications.

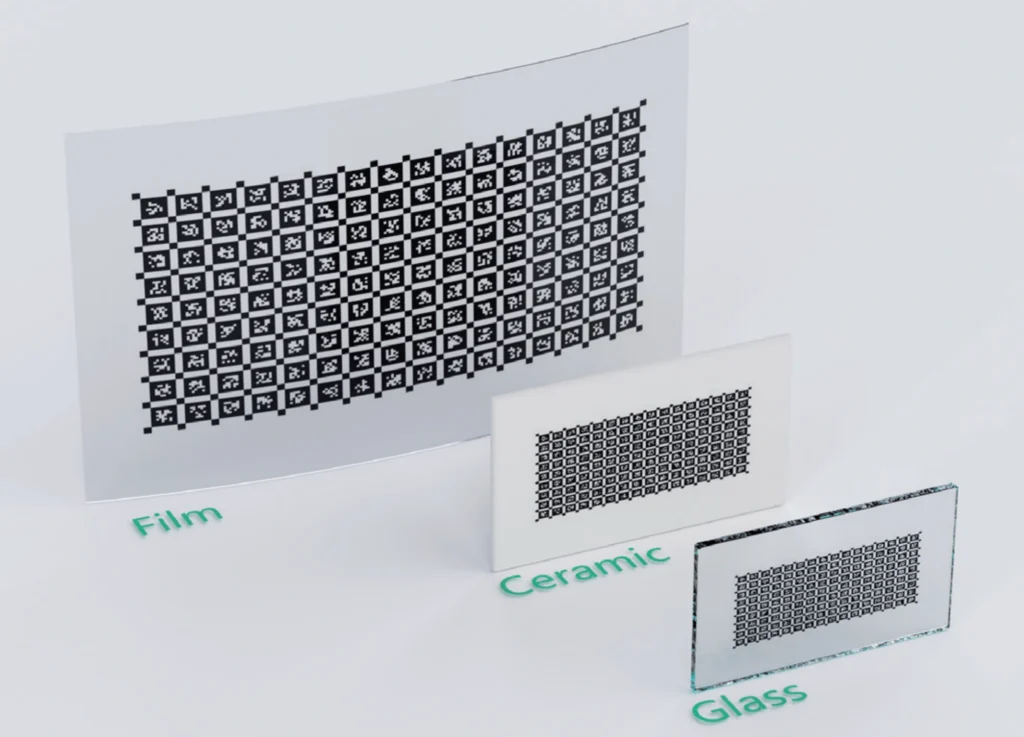

What Are Kalibr/AprilGrid Test Targets? Complete Guide

Kalibr/AprilGrid test targets use AprilTag coded markers for accurate multi-camera and IMU calibration. Available in glass (±1μm accuracy), ceramic (±2μm), and film (±15μm) substrates with various tag sizes and matrices, they enable robust calibration even with partially visible corners.

What Are Halcon Test Targets And How Do They Work?

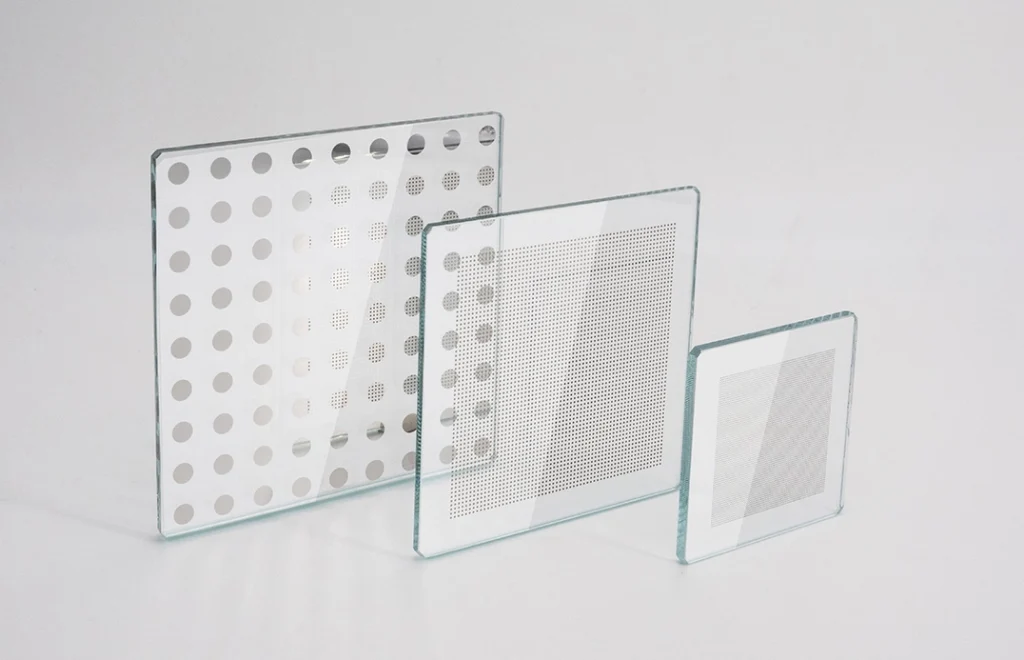

Halcon test targets are precision calibration tools for machine vision systems featuring specific patterns of circles arranged in geometric configurations. Available in various materials (glass, ceramic, film) with different circle diameters (0.1mm-10mm) and accuracy levels (±1μm-±2μm).

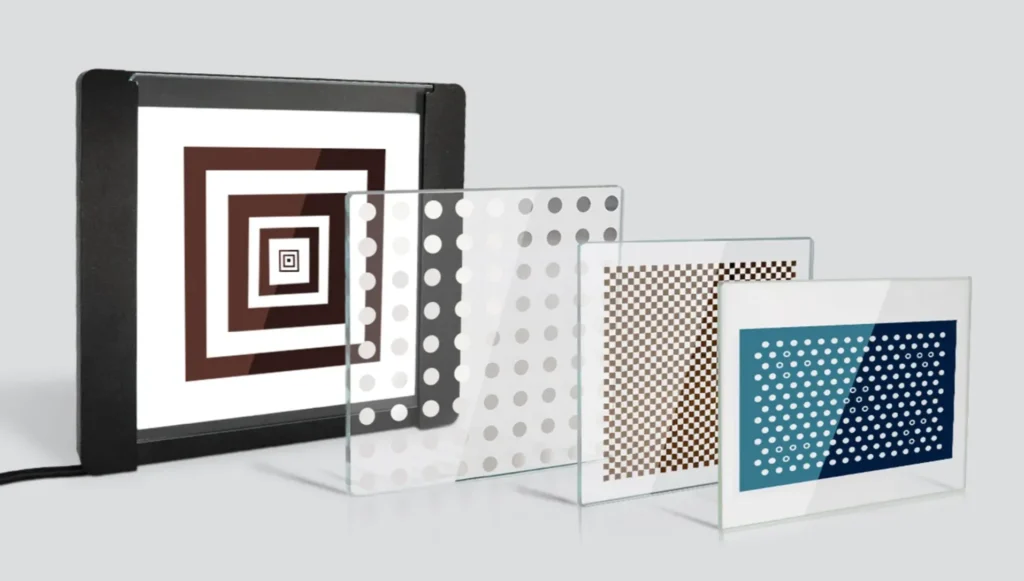

How to Customize a Calibration Target: The Complete Guide

This guide explains how to customize calibration targets by selecting appropriate manufacturing processes based on required precision (from 0.7μm to 0.3mm), choosing optimal materials, specifying custom shapes via laser cutting, and adding special features like backlights or mounting frames.

How to Select the Right Substrate Material for Calibration Targets: A Complete Guide

This guide explains how to select the ideal substrate material for calibration targets. Learn about opaque substrates (ceramic, paper, PE on glass) for front lighting and transparent options (soda lime glass, quartz glass, film) for back lighting, plus considerations for accuracy and environment.