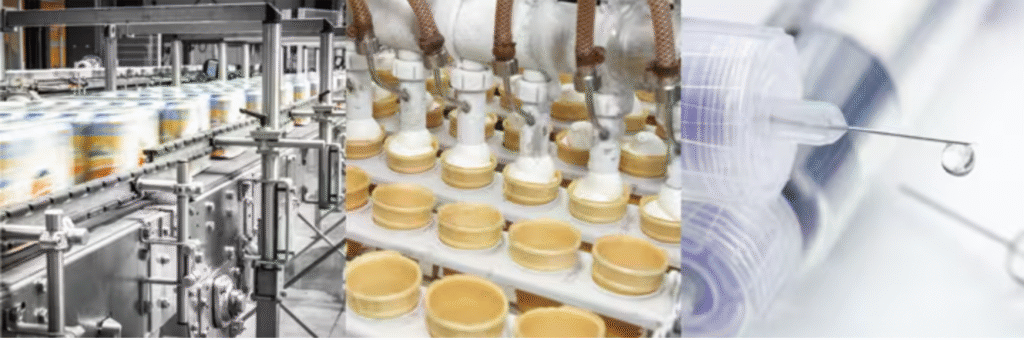

FA Lenses in Food & Pharmaceutical Inspection: Applications, Benefits & Selection Guide

FA lenses in food and pharmaceutical inspection enable critical quality control applications including defect detection, code verification, and contaminant identification. These specialized lenses provide the resolution, contrast, and durability needed for regulatory compliance and consumer safety.