What Is a ChArUco Calibration Board?

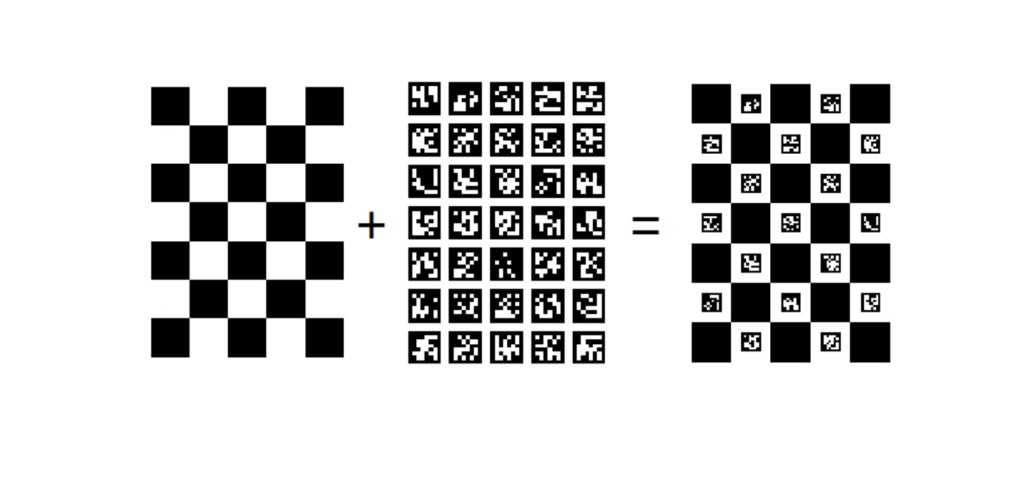

A ChArUco calibration board combines checkerboard corners and ArUco markers in one target. It offers sub-pixel corner detection and robust marker identification, even when part of the board is out of view. This makes it ideal for camera calibration, pose estimation, and multi-camera setups in industrial vision, robotics, and metrology.

Why Engineers Prefer ChArUco Over Standard Checkerboards

A standard checkerboard works well when all corners are visible.

But once the pattern is partly blocked, calibration fails.

ChArUco solves this.

Each square includes a coded ArUco marker.

Even if only a few markers are visible, the software can still calculate the full board pose accurately.

That’s why ChArUco is widely supported by OpenCV, HALCON, and other vision frameworks.

Choose the Right Material for Your Calibration Board

Different applications require different substrates.

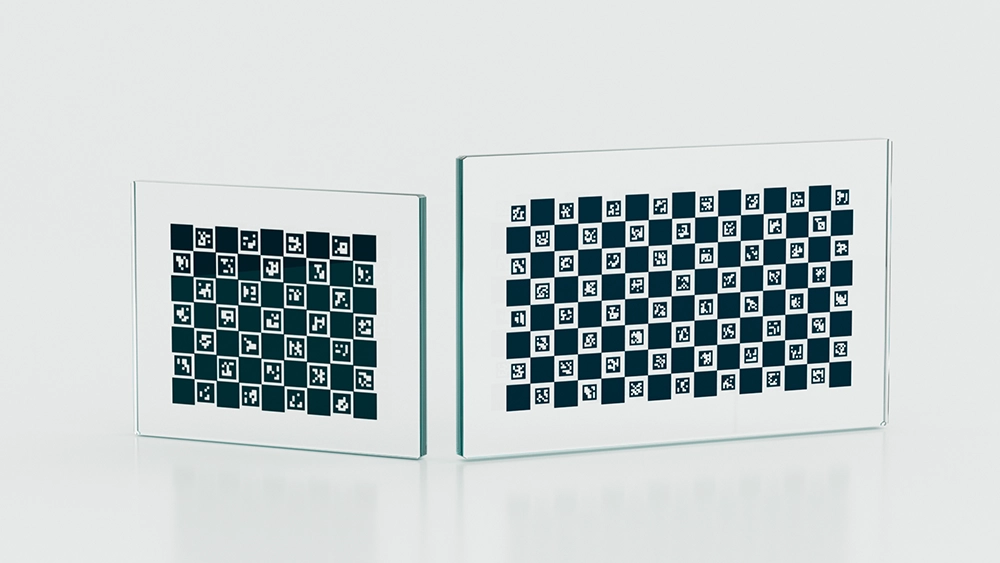

CalibVision offers three main materials, each verified for precision and durability.

| Material | Key Features | Typical Accuracy | Best For |

| Glass | Ultra-flat surface, laser-etched, anti-warp | ±0.3 µm | High-precision lab calibration |

| Ceramic | Rigid, stable, heat-resistant | ±2 µm | Factory floor or industrial setups |

| Film (PET/Mylar) | Lightweight, flexible, cost-effective | ±30 µm | Quick field calibration |

All materials support custom pattern layouts, marker dictionaries, and protective coatings.

ChArUco Pattern Configuration Explained

Each ChArUco board is made to match your camera’s field of view and resolution.

- Start ID: 0–7

- Dictionary: 4×4, 5×5, 6×6, 7×7

- Grid size: 5×5 mm – 15×15 mm

- Edge margins: 10 mm, 15 mm, 20 mm, 30 mm

- Aspect ratio: 16:9 or custom

Choosing the right pattern size helps ensure accurate corner detection across your imaging area.

Precision Grades — From ±0.1 mm to ±0.3 µm

Calibration accuracy depends on surface flatness and pattern geometry.

That’s why all CalibVision targets are inspected under metrology standards.

| Precision Level | Typical Material | Use Case |

| ±1 µm | High-grade glass | Intrinsic calibration, research |

| ±2 µm | Ceramic | Industrial calibration |

| ±15 µm / ±30 µm | Film | Fast field setup |

| ±0.1 mm | Paper | Training or low-cost testing |

Standard ChArUco Camera Calibration Targets Models Available from Stock

You can order directly from stock or request a quick modification.

| Model | Material | Size (mm) | Dictionary | Pattern (mm) | Accuracy |

| LTC-110-05-G | Glass | 110×85 | 4×4 | 5×5 mm | ±1 µm |

| LTC-185-08-G | Glass | 185×110 | 4×4 | 8×8 mm | ±1 µm |

| LTC-230-10-G | Glass | 230×140 | 5×5 | 10×10 mm | ±1 µm |

| LTC-270-12-G | Glass | 270×165 | 5×5 | 12×12 mm | ±1 µm |

| LTC-340-15-FT | Film | 340×200 | 6×6 | 15×15 mm | ±30 µm |

| LTC-460-20-FT | Film | 460×200 | 7×7 | 20×20 mm | ±30 µm |

| LTC-110-05-C | Ceramic | 110×85 | 5×5 | 5×5 mm | ±2 µm |

| LTC-185-08-C | Ceramic | 185×110 | 5×5 | 8×8 mm | ±2 µm |

Customization Options — Design for Your Vision System

Need a specific pattern or size? We produce custom ChArUco targets in 5–7 working days.

You can customize:

- Material and thickness

- Grid and marker dictionary

- Outer frame or mounting holes

- Surface coating or anti-reflection treatment

- Edge margins and overall dimensions

Just send us your drawing or requirements — our engineers will optimize the layout for your camera and workspace.

Why Calibration Accuracy Depends on Target Quality

The accuracy of your camera calibration directly depends on the geometric precision of the calibration board.

Low-cost printed paper targets can introduce distortion or warping.

A deviation of only a few microns can lead to large reprojection errors in 3D measurements.

That’s why CalibVision focuses on ultra-flat glass and ceramic targets with certified dimensional accuracy. Every board is measured, verified, and documented before shipping.

Applications of ChArUco Calibration Boards in Vision Systems

- Machine vision system calibration

- Robot hand-eye coordination

- Multi-camera stereo setups

- 3D reconstruction and depth sensing

- AR/VR imaging and metrology

- Scientific and optical laboratory research

Why Professionals Choose CalibVision

- High-precision fabrication — glass ±0.3 µm, ceramic ±2 µm

- Fast customization — 5–7 days for custom orders

- Broad material range — glass, ceramic, film, paper, CFRP

- Engineering support — optimized for OpenCV / HALCON systems

- Over 100 standard models in stock

CalibVision helps engineers and researchers achieve reliable, repeatable calibration results with confidence.

Start Your Custom Calibration Project Today

🧭 Explore standard models: ChArUco Calibration Boards

📩 Contact our team: sales@calibvision.com

CalibVision — your precision partner in machine vision calibration.