How to Order

Custom Calibration Targets

Customization

Step 1: Select Illumination

Step 2: Choose Substrate

6 Steps

to Custom

Your Calibration Targets

Follow the below 6 steps instruction to get your accurate calibration target.

Step 01

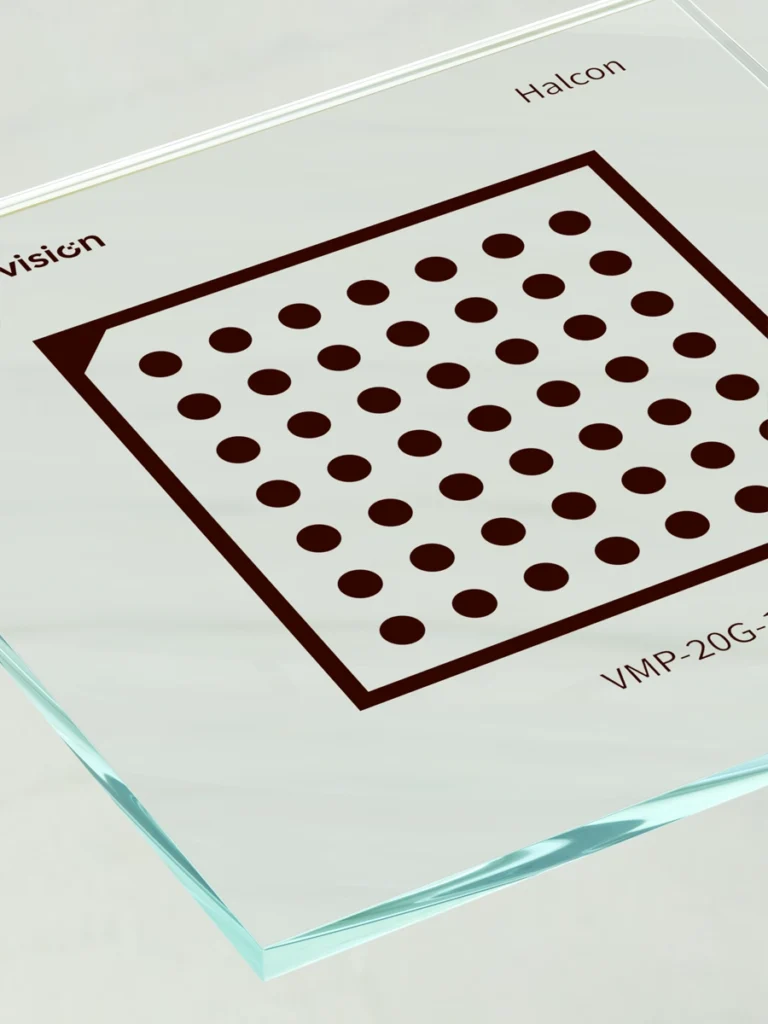

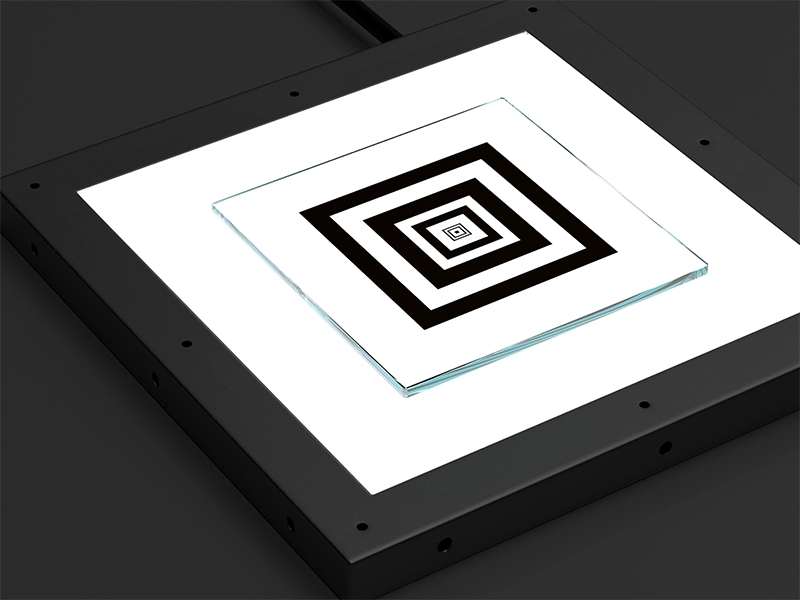

Choose Substrate Material

Backlight Setup(Transmissive)

Soda Lime Glass | Quartz Glass |Acryl | Film

Front lighting Setup(Reflective)

Matte Ceramic | Aluminum | Carbon Fiber Boards

Step 02

Select Accuracy

Choose manufacturing process based on required accuracy: ±10μm, ±1μm, or ±0.5μm, check below form to find your best solution.

| Min. Feature Size (Required Accuracy) | Manufacturing Process | Coating Type | Features | Substrate Recommended |

|---|---|---|---|---|

| ≥ 0.5μm (±1μm) | Laser Writing | Silver Chrome | High Reflectivity | Glass/Ceramic |

| Brown Chrome | Moderate Reflectivity | |||

| Blue Chrome | Low Reflectivity, OD>4.5 | |||

| ≥ 20μm (±2μm) |

Photosensitive Ink |

Black Coating | Non-reflective, OD>5.0 |

Glass/Carbon Fiber/ White PE on Glass |

| ≥ 15μm (±10μm) |

Laser Drawing |

Silver Bromide |

100% Black OD>4.5, Grayscale OD Controllable |

Film |

| ≥ 0.3mm (±0.1mm) | Inkjet | Ink | High Contrast | Photo Paper |

*Example: Need 3μm features with ±15μm accuracy? Chrome on glass is your solution.

Step 03

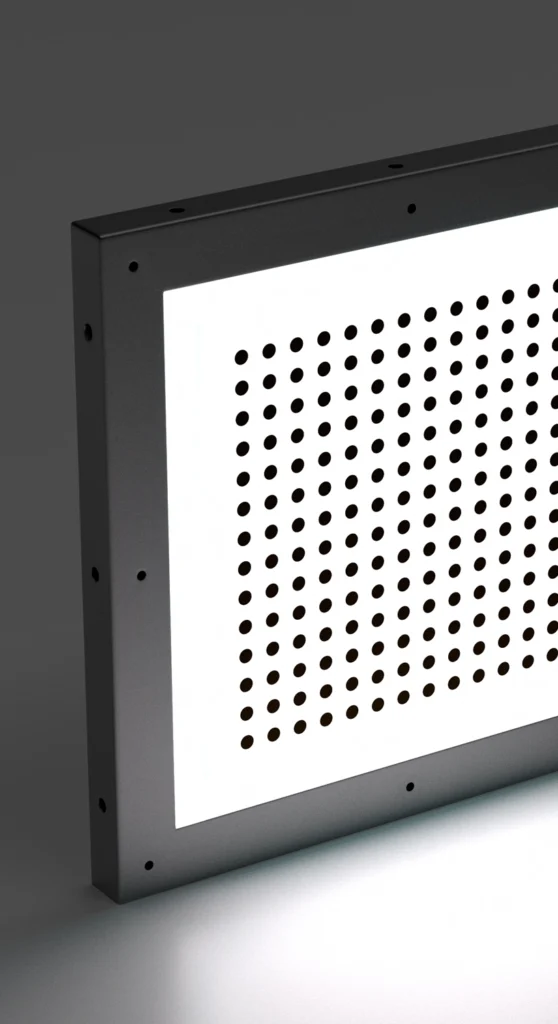

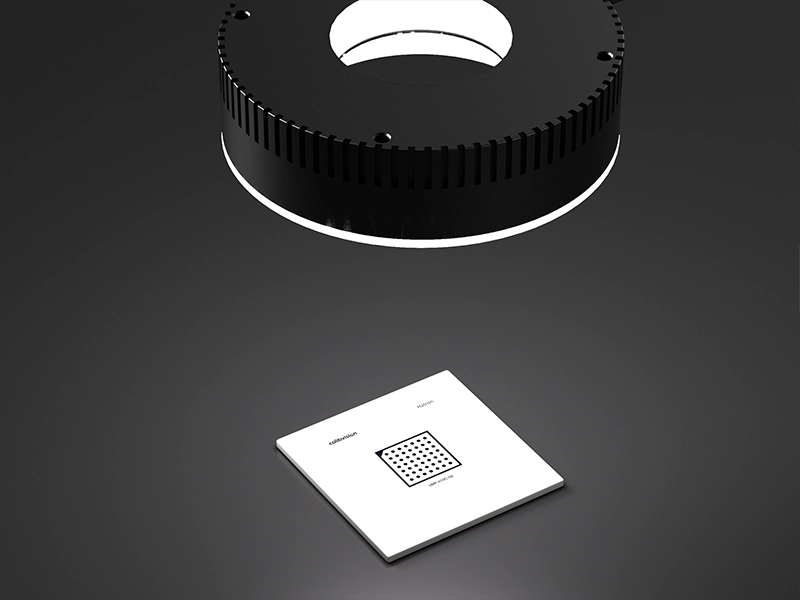

Customize Matched Light Source & Controller (Optional)

Specifically designed to match your calibration target, save time and cost, but most importantly to avoid mismatch when order separately.

Customize Backlight Source

- Maximum Illumination Area: 2.1×1.4m

- Uniformity: >95%

- Red/Infrared Light: Red light or infrared light optional

- Brightness: Adjustable

- Color Temperature: 2700-7000K optional

Step 04

Submit Design and Confirm

Send us your drawing in PDF, DWG, DXF, or JPG format to sales@calibvision.com through calibvision quote form. We also provide a free drawing service . If you do not have a design, our engineer will help fix this. What you only have to do is to review and confirm final manufacturing specifications

Step 05

Quote and Payment

Step 06

Manufacturing & Quality Control &Shipping