What is a Smart Visual Inspection System?

A Smart Visual Inspection System is an advanced optical measurement tool that combines high-resolution cameras, precision optics, and intelligent software to perform detailed visual analysis and measurements without manual calibration. These systems revolutionize quality control processes by automating inspection tasks that previously required complex setups and extensive operator training.

Unlike traditional microscopes or basic vision systems, smart inspection systems like the SVI4K-0745 can automatically detect features, calculate measurements, and generate reports with minimal user intervention.

Why Businesses Need Smart Visual Inspection Technology

Quality control challenges continue to grow as components get smaller and tolerances tighter. Many manufacturers struggle with:

- Time-consuming manual measurements

- Inconsistent results between operators

- Complex calibration procedures

- Poor documentation of inspection results

- Difficulty measuring tiny features

Smart inspection systems address these challenges by providing automated, repeatable measurements that don’t depend on operator skill level.

Introducing the SVI4K-0745 Smart Visual Inspection System

The SVI4K-0745 represents the next generation of visual inspection technology. This all-in-one system eliminates traditional measurement barriers through:

- Auto-calibration technology – measure directly without setup procedures

- Intelligent feature recognition – the system finds measurement points automatically

- One-click data export – instantly generate measurement reports

- 4K imaging at 60 FPS – crystal-clear, blur-free viewing

How It Works: 3 Simple Steps

What makes the SVI4K-0745 revolutionary is its simplicity:

- Power On – The system initializes with automatic calibration

- Select Function – Choose from 18 built-in measurement tools

- Define Range – Select the area to measure

The system automatically recognizes features within your defined area and performs accurate measurements at high speed. No manual calibration required!

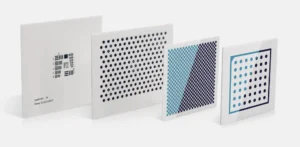

Model Comparison: Choosing the Right SVI4K-0745 for Your Needs

The SVI4K-0745 comes in three specialized configurations:

| Model | Key Feature | Best For |

|---|---|---|

| SVI4K-0745B | Linear zoom adjustment | General inspection tasks |

| SVI4K-0745G | Fixed magnification steps | Repeated measurements at specific magnifications |

| SVI4K-0745D | Extended depth of field | Uneven surfaces and parts with height variations |

All models feature the same core technology: 4K Sony sensors, 0.7-4.5x zoom capability, and intelligent measurement software.

Key Applications Across Industries

Electronic Components

- Microchip pin measurements with sub-micron accuracy

- Solder ball inspection for quality assurance

- Gold wire measurements in semiconductor packaging

- PCB inspection and component verification

In the electronics manufacturing industry, miniaturization continues to push the limits of inspection technology. The SVI4K-0745 excels in this environment, providing sub-micron measurement accuracy for critical components.

For PCB manufacturing facilities, pin spacing and solder quality directly impact product reliability. The system’s automatic feature recognition can identify and measure pin-to-pin distances on microchips with exceptional precision, even when components are irregularly spaced.

A major electronics manufacturer recently reported reducing their inspection time by 65% after implementing the SVI4K-0745, while simultaneously decreasing measurement errors by over 40%.

Manufacturing Quality Control

- Small metal part measurements with instant pass/fail feedback

- Watch component inspection for precision timepieces

- Fine defect detection on finished products

- Surface finish analysis

Watch manufacturers and precision machining operations face unique challenges when inspecting tiny components. The SVI4K-0745’s extended depth of field (D model) allows inspection of three-dimensional parts without constant refocusing.

For quality control teams examining machined parts, the system’s one-click image and data export capabilities streamline documentation. Measurement data can be instantly compiled into tables for statistical process control, while annotated images provide clear visual documentation of any defects or tolerance issues.

Materials Analysis

- Lens and wafer scratch/contamination detection

- Polymer material structure examination

- Fabric and textile quality inspection

When inspecting optical components like lenses and wafers, surface defects may be nearly invisible to the naked eye. The SVI4K-0745’s adjustable quadrant lighting system highlights scratches, dust, and contamination that might otherwise go undetected.

Textile manufacturers benefit from the system’s ability to analyze fiber quality and weave patterns with exceptional clarity. The high-resolution imaging reveals material characteristics that impact product performance, from synthetic polymers to natural textiles.

Precision Operations

- Micro-assembly guidance and verification

- Small component soldering assistance

- Detailed visual inspection for compliance requirements

For operators performing delicate assembly work, the SVI4K-0745 provides hands-free magnification and measurement. The continuous zoom range delivers the perfect view for soldering tiny components, wire bonding, and precision positioning tasks.

The system’s stable mounting platform reduces vibration, while the adjustable LED lighting ensures optimal illumination without shadows or glare.

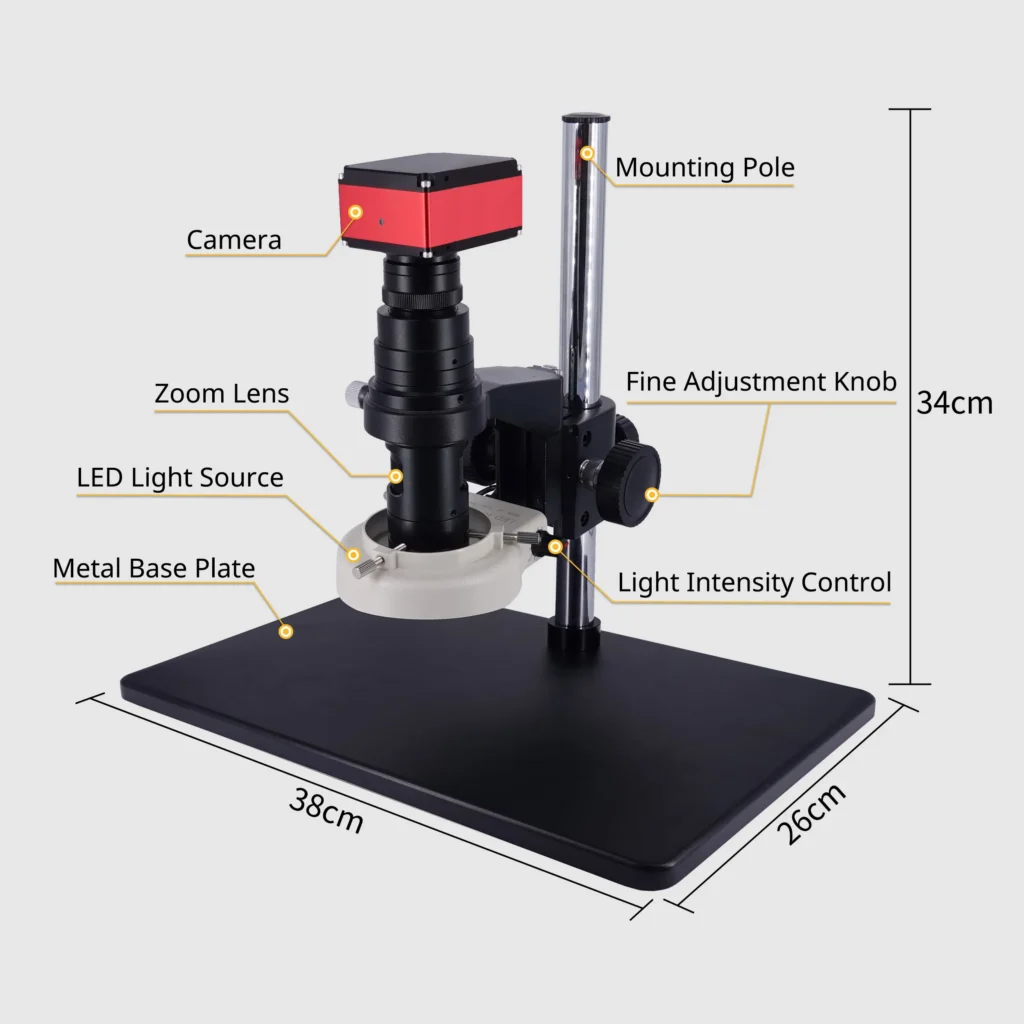

Complete System Components

The SVI4K-0745 includes everything needed for immediate operation:

Main Camera Stand

- High-resolution 4K industrial camera

- 34cm height support column for versatile positioning

- Variable magnification optics (0.7-4.5x zoom lens)

- Built-in LED illumination with brightness control

- Precision focus adjustment

- Stable metal base plate (38cm × 26cm)

LED Ring Light

- Secure mounting brackets for optimal positioning

- Brightness adjustment dial for perfect illumination

- A/B/C/D quadrant lighting selectors for controlling shadows

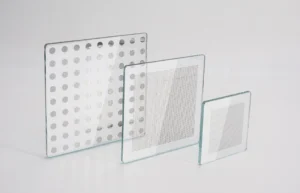

Optical Components

- C-Mount Interface: Standard lens connection

- Magnification Scale: Zoom level indicator

- Magnification Adjustment Ring: Focus control

Camera Interface

- Power Input: Main connection port

- USB 2.0 Port: Data transfer connection

- USB 3.0 Port: High-speed data transfer

- GigE Connection: Network interface

- HDMI Output: Direct display connection

Why Choose the SVI4K-0745 Over Traditional Systems?

Time Savings

Traditional visual inspection systems often require 10-15 minutes of calibration before each use. The SVI4K-0745 works immediately after powering on, saving hours each week.

Accuracy Improvement

By removing human variables from the measurement process, the SVI4K-0745 delivers consistent results regardless of operator experience.

Ease of Use

Even users with minimal training can obtain laboratory-grade measurements with just three simple steps.

Data Integration

One-click reports make documentation effortless and integrate easily with quality management systems.

Frequently Asked Questions

Does the system require regular recalibration?

No. The SVI4K-0745 performs automatic calibration during startup and maintains accuracy without user intervention.

Can measurements be exported to other systems?

Yes. The system can export measurement data in standard formats compatible with Excel, quality management software, and statistical process control systems.

What types of measurements can the system perform?

The SVI4K-0745 includes 18 built-in measurement tools, including point-to-point, line-to-line, circle, arc, angle, and area calculations.

Is special training required?

The system is designed for immediate use with minimal training. Most users become proficient within minutes of setup.

Conclusion

The SVI4K-0745 Smart Visual Inspection System represents a significant advancement in quality control technology. By combining intelligent software with precision optics and 4K imaging, it delivers professional-grade measurements without the complexity of traditional systems.

Whether you’re inspecting electronic components, analyzing materials, or verifying product quality, the SVI4K-0745 provides the accuracy and ease of use that modern manufacturing demands.