A Halcon calibration target is a precisely manufactured physical object with known geometric properties used to calibrate cameras and machine vision systems in Halcon software. It serves as a reference pattern that enables the software to determine camera parameters like focal length, distortion, and positioning for accurate measurements.

Understanding Halcon Calibration Targets

Think of it like this: Just as you need a ruler to measure distances accurately, cameras need calibration targets to “understand” what they’re seeing in the real world. A Halcon calibration target is essentially a smart ruler with special patterns that cameras can recognize and use for precise measurements.

How Halcon Calibration Targets Work

The Basic Process:

- Place the target in the camera’s view

- Capture multiple images from different angles and positions

- Halcon software analyzes the known patterns in the images

- Camera parameters are calculated based on how the patterns appear

- System is now calibrated for accurate real-world measurements

Key Components:

Known Geometry: Every measurement on the target is precisely manufactured – the software knows exactly how big each pattern should be in the real world.

Recognizable Patterns: Features like circles, dots, or geometric shapes that Halcon’s algorithms can automatically detect and analyze.

Multiple Reference Points: Various patterns across the target provide numerous calibration points for enhanced accuracy.

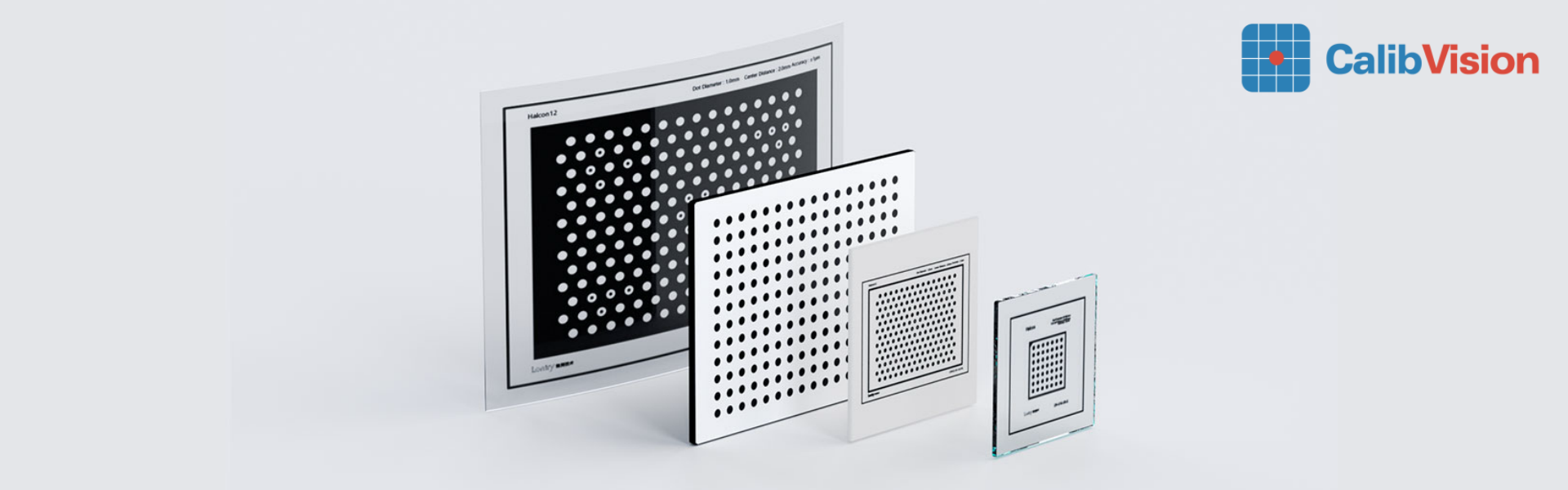

Types of Halcon Calibration Targets

Standard Patterns:

- Circular dot arrays – Most common for general calibration

- Checkerboard patterns – Alternative geometric reference

- Hexagonal arrangements – Specialized applications

- Sheet-of-light objects – For 3D scanning calibration

Customization Options:

Users can create custom targets using Halcon’s create_caltab operator, specifying:

- Dot size and spacing

- Overall dimensions

- Pattern arrangement

- Material specifications

Why Halcon Calibration Targets Matter

Accuracy Benefits:

- Precise measurements – Enables sub-pixel accuracy in vision applications

- Distortion correction – Removes lens distortion effects

- 3D reconstruction – Establishes geometric relationships for depth perception

- Consistent results – Ensures reliable performance across different conditions

Real-World Applications:

- Quality control inspection – Measuring parts with high precision

- Robot guidance – Accurate positioning for pick-and-place operations

- 3D scanning – Creating accurate digital models

- Dimensional analysis – Industrial measurement applications

Simple Analogy

Camera calibration is like teaching someone to use a measuring tape correctly. The Halcon calibration target is like a practice object with known dimensions. By measuring this practice object multiple times from different angles, the person (camera) learns how to measure accurately in the real world.

Technical Implementation

Software Integration:

- Halcon 12 and newer versions offer enhanced calibration target support

- MVTec Software provides comprehensive calibration tools

- Automatic detection algorithms identify target patterns

- Parameter optimization ensures best calibration results

Usage Workflow:

- Select appropriate target based on application requirements

- Position target in various orientations within camera field of view

- Capture calibration images (typically 10-20 different poses)

- Run calibration algorithm using Halcon software

- Validate results and apply to vision system

Choosing the Right Target

Consider these factors:

- Working distance – Size of target relative to camera distance

- Accuracy requirements – Precision needed for your application

- Environmental conditions – Lighting and mounting constraints

- Target material – Glass, ceramic, or printed options available

Professional Tip: The target should fill approximately 1/3 to 2/3 of the camera’s field of view for optimal calibration results.

Halcon calibration targets are essential tools that transform cameras from simple image capture devices into precise measurement instruments, enabling reliable machine vision applications across industries.