When it comes to calibrating optical measurement systems—from LiDAR sensors in autonomous vehicles to quality control cameras in manufacturing—precision matters. That’s where diffuse reflectance standards come in. These calibration targets provide the reference points that ensure your optical systems measure light accurately and consistently.

What Are Diffuse Reflectance Standards?

Diffuse reflectance standards are precision-engineered surfaces with known, controlled reflectance values. Unlike mirrors that reflect light in a single direction (specular reflection), these standards scatter light evenly in all directions—a property known as Lambertian reflection.

Think of them as the “rulers” of the optical world. Just as you need a calibrated ruler to measure length accurately, optical systems need calibrated reflectance targets to measure light correctly.

Why Reflectance Calibration Matters

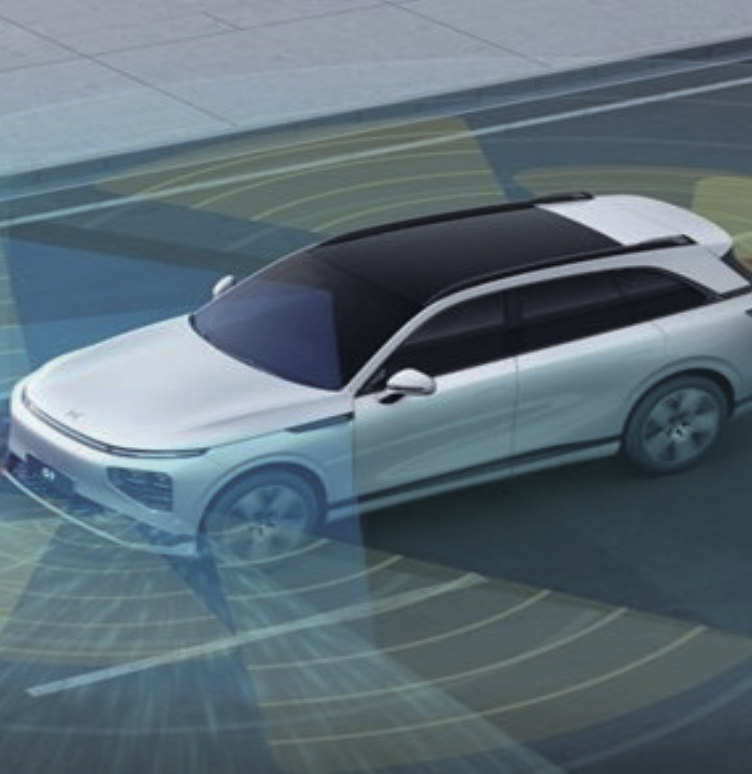

Modern optical systems power critical applications across industries. Autonomous vehicles rely on LiDAR sensors to “see” the road. Manufacturing lines use machine vision to detect defects. Robotic vacuum cleaners navigate homes using optical sensors.

All these systems make decisions based on how much light reflects off surfaces. If the calibration is off by even a few percentage points, it can mean the difference between a self-driving car correctly identifying an obstacle or missing it entirely.

Key Characteristics of Quality Reflectance Standards

Technical Specifications

| Parameter | Specification |

|---|---|

| Reflectance Range | 1-99% (Customizable) |

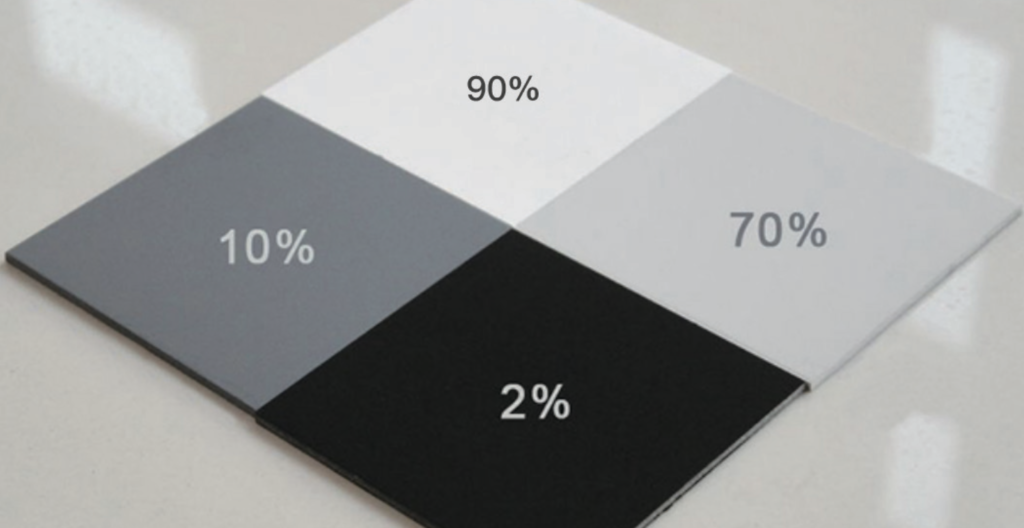

| Standard Reflectivity Levels | 2%, 10%, 50%, 70%, 90% |

| Surface Material | Matte coating |

| Thickness | 3mm (Standard) |

| Color Options | Black, white, grayscale (customizable) |

| Size Range | Customizable, maximum 3×5m |

| Spectral Response | Uniform across wavelength range |

| Wavelength Range | 200-2000nm |

| LiDAR Wavelengths | 850nm, 905nm, 940nm, 1550nm |

| Lambertian Property | Excellent diffuse reflection |

| Coating Type | Special precision ink |

| Waterproof | Yes (customizable coating) |

| Mounting Accessories | Adjustable brackets, sliders, bases (height and angle adjustable) |

| Packaging | Customizable aluminum protective case |

| Applications |

– Autonomous driving sensor testing – Long-distance LiDAR calibration – Camera detection systems – Robotic vacuum cleaner testing – Smart device calibration |

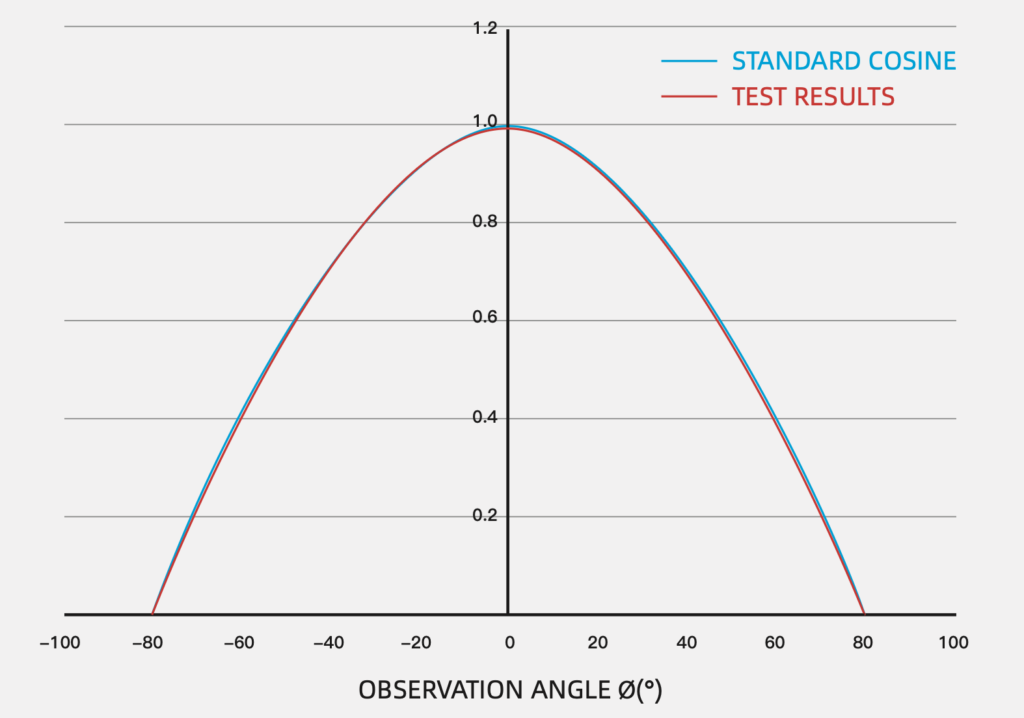

Lambertian Properties

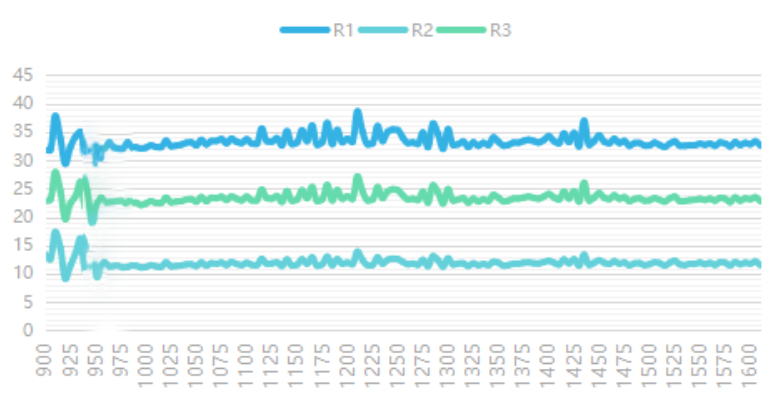

The best diffuse reflectance standards follow Lambert’s cosine law—they reflect light uniformly regardless of the viewing angle. This consistency eliminates one major variable in optical measurements, making calibration more reliable.

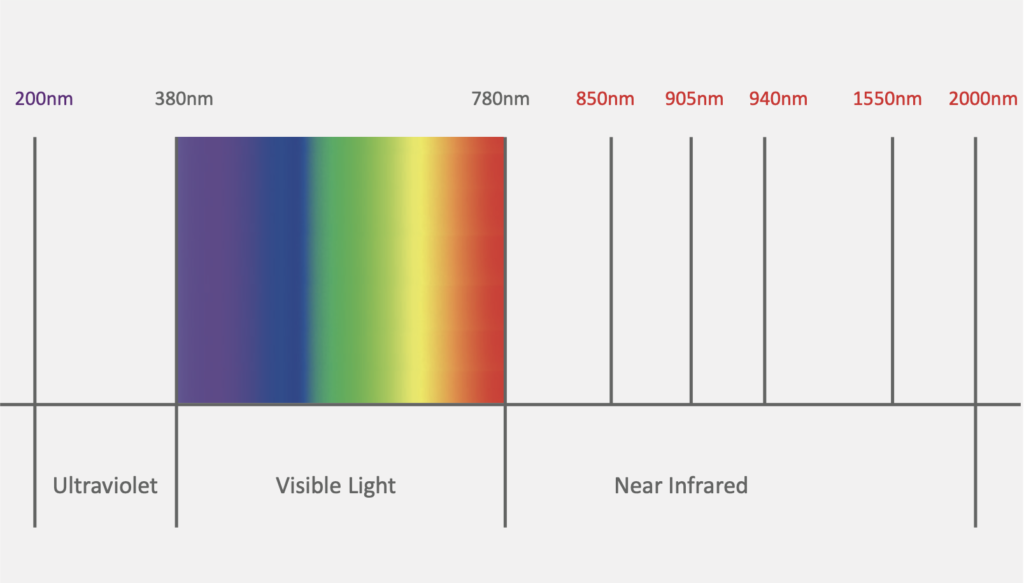

Spectral Uniformity

Quality standards maintain consistent reflectance across different wavelengths. CalibVision’s diffuse reflectance standards, for example, operate uniformly across the 200-2000nm spectrum, covering ultraviolet through near-infrared ranges critical for automotive LiDAR systems.

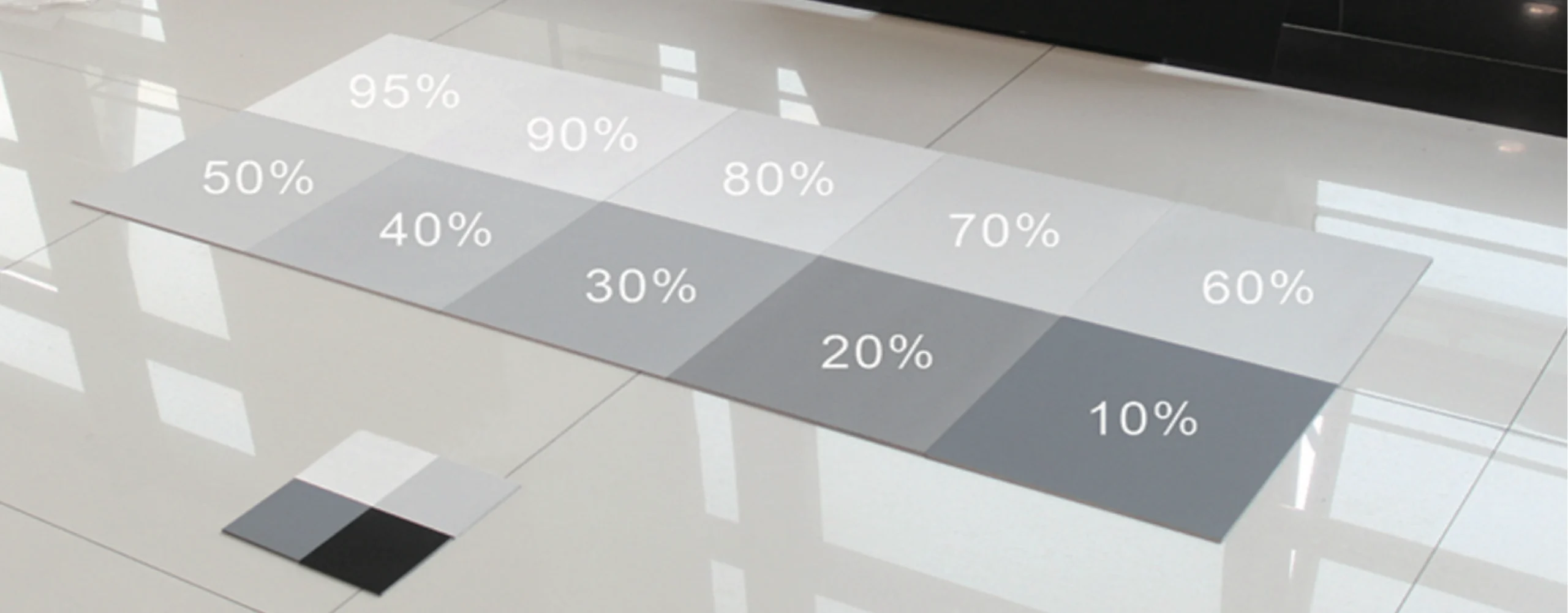

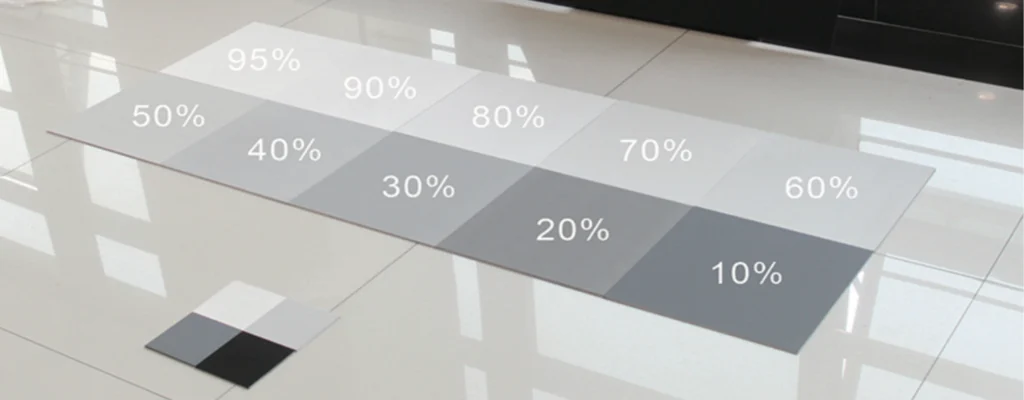

Customizable Reflectance Levels

Real-world surfaces rarely reflect 100% of light. Black asphalt might reflect 5% of incident light, while white road markings reflect 80% or more. Calibration standards need to match these real-world conditions, which is why reflectance options typically range from 2% (nearly black) to 99% (nearly perfect white).

Applications Across Industries

01 Autonomous Driving

Automakers use diffuse reflectance standards to calibrate the sensor fusion systems that combine camera and LiDAR data. Testing protocols require verification at multiple reflectance levels to ensure vehicles can detect everything from dark-colored cars to bright road signs.

02 LiDAR Development

Long-range LiDAR systems, operating at wavelengths like 905nm or 1550nm, need specialized calibration targets. Large-format reflectance panels (up to 3×5 meters) enable testing at distances exceeding 200 meters—critical for highway-speed autonomous driving.

03 Machine Vision

Manufacturing quality control systems use reflectance standards to ensure consistent color measurement and defect detection. Whether inspecting smartphone camera modules or automotive paint finishes, calibrated references ensure production stays within specification.

04 Robotics

From warehouse automation to consumer products like robot vacuums, mobile robots use optical sensors for navigation. Reflectance standards help calibrate these systems to work reliably across different floor types and lighting conditions.

What to Look for in a Reflectance Standard

Durability

Industrial environments are tough. Look for standards with waterproof coatings, scratch-resistant surfaces, and protective housing. The target that works perfectly in the lab needs to survive repeated use in production environments.

Traceability

Professional applications often require calibration certificates traceable to national standards (like NIST in the United States). This documentation proves your measurements meet industry requirements and regulatory standards.

Flexibility

Different applications need different configurations. Portable panels for field testing. Wall-mounted targets for production lines. Adjustable brackets for research labs. The right solution adapts to your specific workflow.

Long-Term Stability

Calibration standards should maintain their specified reflectance values over years, not months. Special coatings and materials resist environmental degradation, UV exposure, and contamination.

Technical Considerations

Wavelength Range

Match your standard’s wavelength range to your application. Visible spectrum work (400-700nm) has different requirements than near-infrared LiDAR calibration (850-1550nm)

Surface Finish

Matte surfaces provide diffuse reflection. The surface coating needs to eliminate any glossiness that would introduce specular reflection and compromise measurement accuracy.

Size Requirements

Camera calibration might need only a 10×10cm target, while long-range LiDAR testing demands panels several meters across. Consider both your current needs and potential future requirements.

Practical Implementation

Calibration Setup

Position reflectance standards at appropriate distances for your measurement geometry. Ensure even illumination and stable environmental conditions. Many systems require multiple reflectance levels—typically 2%, 10%, 50%, and 90%—to characterize linearity across the measurement range.

Maintenance

Keep standards clean using appropriate cleaning methods specified by the manufacturer. Store in protective cases when not in use. Verify calibration periodically, especially after environmental exposure or physical handling.

Integration with Test Systems

Modern reflectance standards often integrate with mounting systems, allowing quick positioning and angle adjustment. Combination targets that include both geometric patterns (like ChArUco boards) and reflectance zones enable simultaneous geometric and radiometric calibration.

The Bottom Line

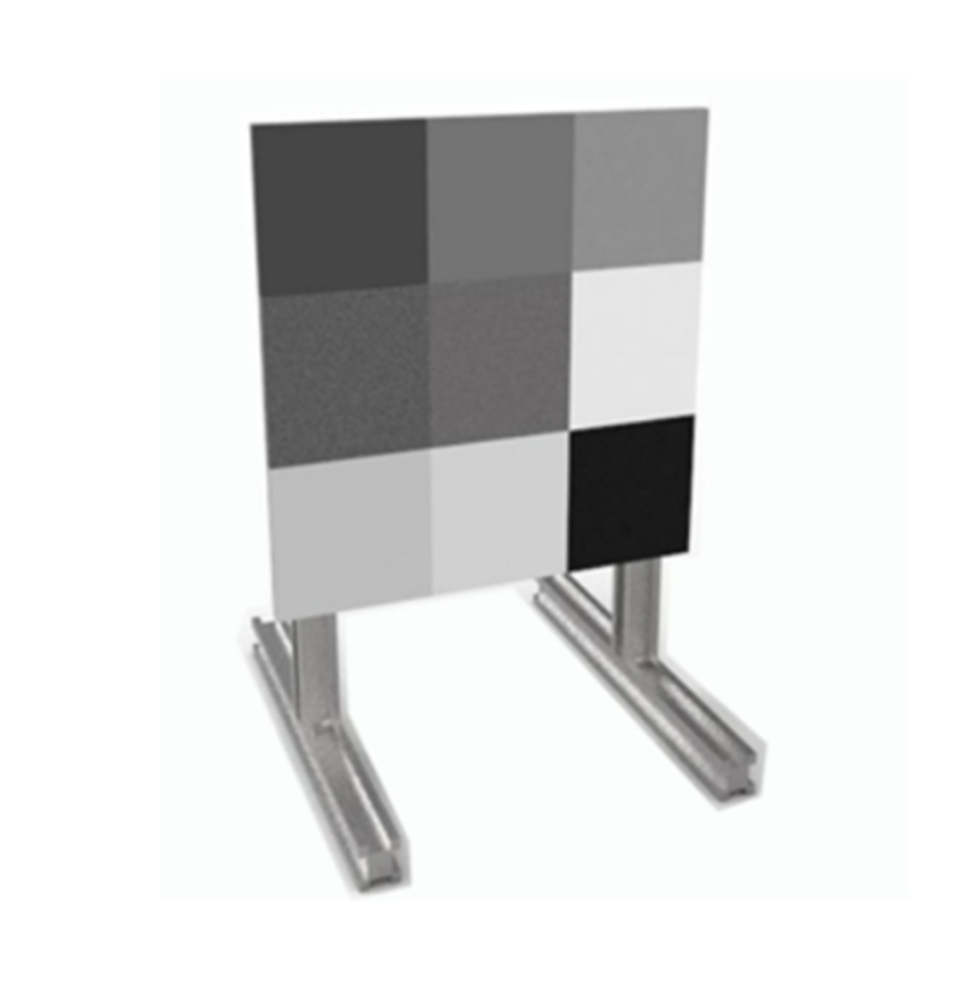

Diffuse reflectance standards might seem like simple gray and white panels, but they’re precision instruments that enable accurate optical measurements across industries. From ensuring your smartphone camera reproduces colors correctly to helping autonomous vehicles navigate safely, these calibration tools play a critical role in modern technology.

Whether you’re developing next-generation LiDAR systems, setting up machine vision for quality control, or conducting optical research, investing in quality reflectance standards ensures your measurements are accurate, repeatable, and trustworthy.

Ready to calibrate your optical systems? Explore CalibVision’s complete line of diffuse reflectance standards, available with custom reflectance values, multiple sizes, and full calibration documentation. Contact our technical team to discuss your specific application requirements.

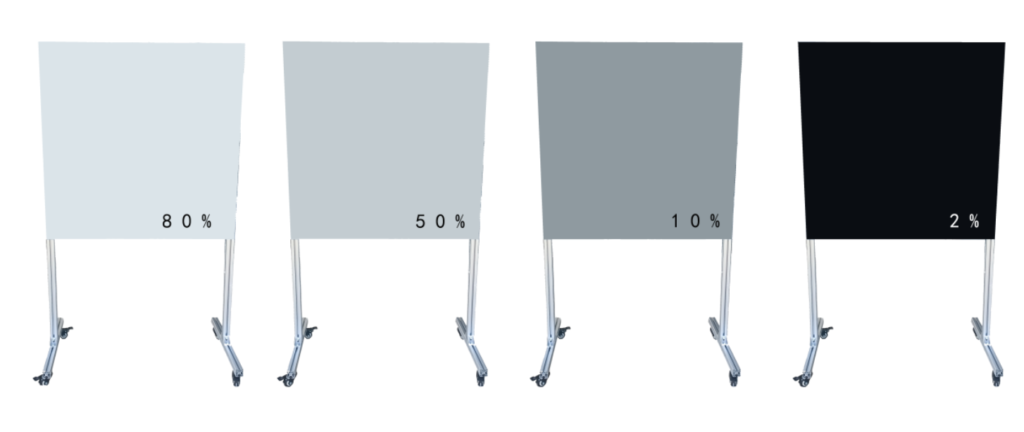

Diffuse Reflectance Standards

Diffuse Reflectance Standards for Autonomous Driving & LiDAR Testing

- Reflectance with 10% to 90% options

- Excellent Lambertian Surface, uniform angular response for accurate LiDAR returns

- Spectral 400-1100nm wavelength compatibility (UV-VIS-NIR spectrum)

- Automotive-Grade Durability, Waterproof, temperature-stable coating

- Custom target sizes up to 3×5 meters

- Custom 1-99% reflectance available

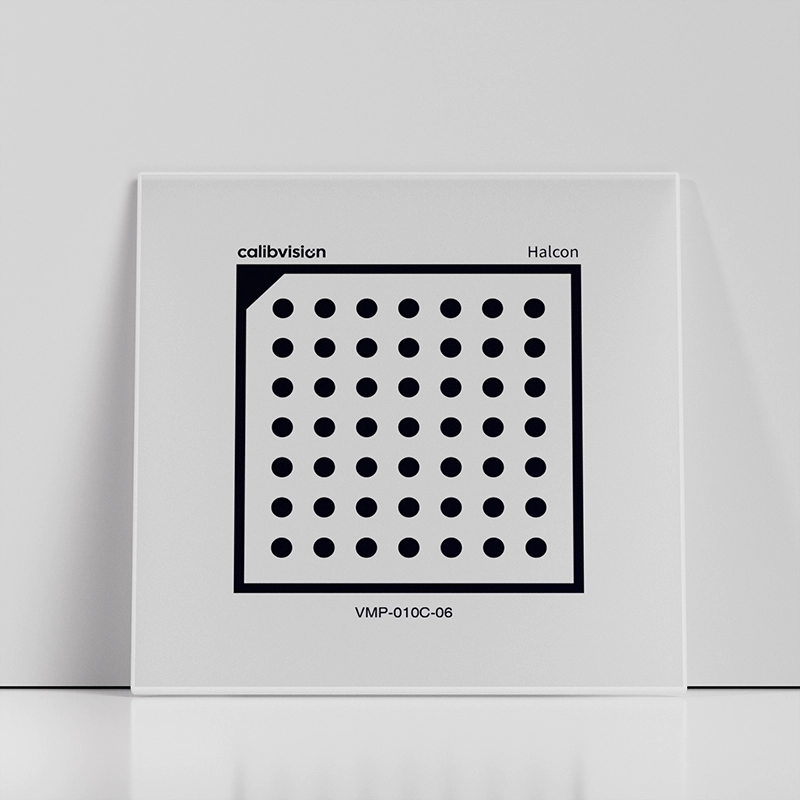

Halcon Calibration Target

Halcon Calibration Target Machine Vision Camera Calibration Board

- Pattern on soda lime glass and matte ceramic;

- Standard arrays: 7×7 | 9×9 available

- 30 in-stock models from 10×10mm to 135×135mm;

- Low-reflective brown chrome coating;

- Custom available for any size, pattern, shape and materials.

- Ideal for: Halcon/ActiveVision calibration software, X-Y stage distortion testing, AOI certification, optical metrology, and machine vision applications requiring micron-level accuracy.